Chapter 9

Page no. 1250

JC-DR-A-229.fm

GE Healthcare

Senographe DS

Revision 1

Service Information and Procedures Class A 2385072-16-8EN

Job Card D/R A229 - Rotation Brake

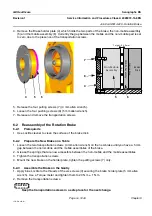

3. Loosen the pulling screws (7) until they protrude by 3 mm from the holder plate.

4. Tighten the pushing screws (8) to reduce the gap between the mobile and non mobile parts of the

brake. View the gap through the four openings and continue until the gap is close to 0 mm (starting

value for the next step).

5. Connect the Brake cable (W219) to the Rotation Board (connector J6).

6-3

Brake Positioning Adjustments

1. Use a 0.15 mm feeler gauge as shown in the illustration

to avoid touching the springs:

1. Try to insert the feeler gauge through the left side of

the opening (E), loosen the pushing screw until the

feeler gauge slips in,

2. Try to insert the feeler gauge through the right side of

the opening (F), loosen the pushing screw until the

feeler gauge slips in,

3. Try to insert the feeler gauge through the right side of

the opening (G), loosen the pushing screw until the

feeler gauge slips in,

4. Try to insert the feeler gauge through the left side of

the opening (H), loosen the pushing screw until the

feeler gauge slips in,

2. Check for each opening that:

1. The 0.15 mm feeler gauge slips in.

2. The 0.18 mm feeler gauge does not enter. If it does, reinsert the 0.15 mm feeler gauge and

retighten the appropriate pushing screw.

3. Tighten the four pulling screws.

6-4

Check the Rotation Movement

1. Move the compression paddle out of compression. Then check that all four sets of arm left/right con-

trol buttons are operational (check each button for rotation movement of column).

2. Rotate the arm to its left and right limits. Software preset limits should stop movement (185° counter-

clockwise, 165° clockwise).

6-5

Brake Fine Adjustment

During arm movement, check for any noise that indicates excessive friction or binding.

7

COMPLETION

None

E

G

H

F