Chapter 9

Page no. 1066

JC-TSG-A-016.fm

GE Healthcare

Senographe DS

Revision 1

Service Information and Procedures Class A 2385072-16-8EN

Job Card TSG A016 - Rotation Movement Troubleshooting

3-5

Grease Rotation Parts

•

Clean the Rotation parts with a Apply Loctite 7063 Super Cleaner (or equivalent, e.g. 3M Citrus

Based Industrial Cleaner) and a cloth until all of the old grease is fully removed.

•

Rotate the arm between the limits of -165° and +185°, to as many

positions as required to fully inspect and grease the gears.

CAUTION

After each movement, switch OFF power while inspecting

and greasing.

•

Apply a light film of

Grease (for Lift and Rotation)

as required to the

teeth of the worm gears and spur gears.

•

Do not apply excess grease

:

the quality of greasing is more important than the quantity.

•

Use a brush to apply grease

:

so as to avoid direct skin contact as far as possible.

•

Use a suitable cloth to remove excess grease.

•

Take care to ensure that you do not apply grease to the cog wheel

of the Rotation Potentiometer. Grease on the cog wheel of the

Rotation Potentiometer causes a bad connection, resulting in

unexpected rotation errors.

CAUTION

Do not use any other type of grease, other than Grease for

Lift and Rotation (5212483) (Orapi CT FLON 607).

5. Once you have finished applying grease to the all the Rotation parts, use the slow speed Arm Control

buttons to rotate the Arm over the whole range two times in slow speed.

6. Use the fast speed Arm Control buttons to rotate the Arm over the whole range a few times in fast

speed.

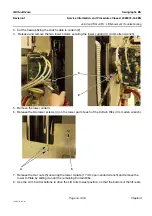

7. Check how grease has been spread to the Rotation parts. Examples of well spread grease, smoothly

and uniformly along the whole radius of the Rotation gear, with no splattered grease are shown in

illustration 4.