GE Healthcare

Senographe DS

Revision 1

Service Information and Procedures Class A 2385072-16-8EN

Job Card D/R A228 - Rotation Motor

Page no. 1245

Chapter 9

JC-DR-A-228.fm

6-2

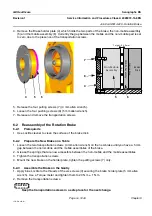

Reassembly of the Rotation Motor

Reverse the disassembly procedure.

Add the following step to the reassembly procedure:

•

Apply blue Loctite to the threads of the motor

securing screws before tightening them.

•

Ensure that there is a gap of 0.2 mm - 0.3 mm

as indicated in the illustration.

•

The replacement Rotation Motor will have an

earth cable, so ensure you connect and route

the earth cable to the top right corner motor fix-

ing plate as shown above. When routing the

earth cable, make sure all excess cable is

secured using a cable tie so that the excess

cable cannot interact with other moving parts of

the Gantry.

•

When routing the Motor cables W206 and

W205 to the Rotation Board (connector J10 and

J9), ensure that they are routed and secured

with cable ties as indicated in the illustration.

6-3

Check the Rotation Movement

1. Move the compression paddle out of compression. Then check that all four sets of arm left/right con-

trol buttons are operational (check each button for arm rotation movement).

2. Rotate the arm to its left and right limits. Software preset limits should stop movement (185° counter-

clockwise, 165° clockwise).

7

COMPLETION

None

Motor

Gap

Cable

Tie

Tie

Cable