GE Healthcare

Senographe DS

Revision 1

Service Information and Procedures Class A 2385072-16-8EN

Job Card TSG A016 - Rotation Movement Troubleshooting

Page no. 1067

Chapter 9

JC-TSG-A-016.fm

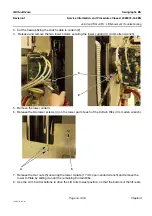

ILLUSTRATION 4 - EXAMPLES OF WELL APPLIED GREASE ON ROTATION PARTS

If there are some areas where no grease exists, apply grease to these areas, rotate the Arm again in

slow and fast speeds, and check the greasing again.

3-6

Rotation Gas Spring Checks

1. Ensure the Tube Head covers and Handle are installed on the Arm.

2. Remove the Breast Support.

3. Rotate the Arm to +90°.

4. Use string to attach a 2 kg (11 lbs) weight to top of the handle, then use the slow speed Arm Control

buttons to rotate the Arm back to 0° in slow speed.

While moving the Arm back to 0°:

a. Check on the Gantry LCD Display whether the following Rotation related errors appear:

•

112/011 - Rotation control error

•

112/012 - Rotation control error

•

112/023 - Rotation control error

b. Visually check that the speed of the rotation movement is constant.

If there are no Rotation related errors/warnings and the movement is constant, the Rotation Gas

Spring is in good condition, and you must continue with the troubleshooting tasks in illustration 1

If there are Rotation related errors/warnings and/or the movement is not constant, the Rotation Gas

Spring needs changing according to