COPYRIGHT © 1999 CANON INC. CANON imageRUNNER 400/330 REV.0 JAN. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

8-9

CHAPTER 8 PAPER DECK

D. Deck Lifter

1. Lifter Movement

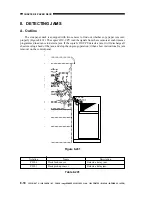

The lifter of the deck is connected to a reel by means of a cable, and is driven by the deck lifter

motor (M102). The lifter is moved up or down by switching the direction of motor rotation.

When the deck (compartment) is pushed inside the copier, the deck open detecting switch

(SW101) is pushed, and the lifter starts and continues to move up when the deck open sensor

(PS109) detects the light-blocking plate until the deck lifter position sensor (PS104) detects the top

surface of the paper placed on the lifter.

The deck lifter upper limit sensor (PS103) is used to prevent damage to the deck, as could

occur should the deck fail to move up after the sensor lever blocks the deck lifter position sensor.

The lifter states to move down, on the other hand, when the deck open switch (SW100) is

pressed, and continues to move down until the lifter leaves the sensor lever of the deck paper

supply position sensor (PS107), i.e., falling edge of the sensor signal.

When copy paper is supplied and the lever of the deck paper supply position sensor is pushed,

the lifter moves farther down until the copy paper leaves the sensor lever. The lifter repeats this

operation each time paper is supplied until the deck lifter lower limit detecting switch (SW102) is

pushed (maximum paper supply position).

The copier's DC-CPU keeps track of the states of the sensors related to lifter operation, and if

the deck paper supply position sensor(PS107) is '0' while both the deck lifter position sensor

(PS104) and the deck level sensor position sensor (PS108) are '1', the copier's control panel will

indicate "E041." (Such a combination of states, however, is highly unlikely.)