COPYRIGHT © 1999 CANON INC. CANON imageRUNNER 400/330 REV.0 JAN. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

13-3

CHAPTER 13 MAINTENANCE AND SERVICING

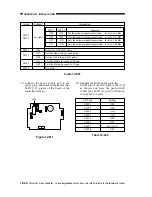

III. SCHEDULED SERVICING CHART

Caution:

1. As a rule, provide scheduled servicing every 120,000 copies.

2. Check the service book before setting out on a visit, and take replacement parts as needed.

No.

1

2

3

4

5

6

7

8

Work

Meet the person in charge.

Record the counter reading.

Make test copies.

Clean the optical assembly:

Reflecting plate

Lens

No. 1, 2, 3 mirrors

Dust-proofing glass

Standard white plate

Clean the transfer guide:

Transfer guide plate

(upper, lower)

Transfer charging

assembly guide rail

Clean the separation/feeding

assembly:

Separation static eliminator

Feeding belt

Clean the fixing/delivery

assembly:

Fixing assembly inlet guide

Separation claw (upper,

lower)

Provide scheduled servicing

according to the number of

copies made.

Remarks

*Standard of 2.5 ±1.0 mm.

Use a blower brush; if the dirt

is excessive, use alcohol.

Dry wipe the standard white

plate.

Be sure to remove the drum

unit before cleaning.

When replacing the drum

cartridge, clean the separation

claw (upper, lower).

Checks

Checking the conditions.

Check the faulty copies.

a. Image density

b. Background for soiling

c. Characters for clarity

d. Leading edge margin*

e. Fixing, registration, and

back (for soiling)

f. Counter operation