CHAPTER 7 PICK-UP/FEEDING SYSTEM

7-4

COPYRIGHT © 1999 CANON INC. CANON imageRUNNER 400/330 REV.0 JAN. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

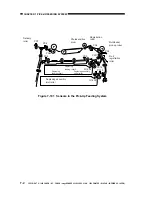

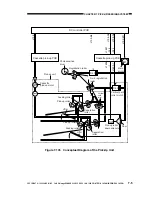

B. Sequence of Operations (pick-up from the cassette)

1. Pick-Up Operation

The paper inside the cassette is held up by the lifter, and it is in contact with the pick-up roller

at time of pick-up.

The pick-up roller is driven by the cassette pick-up motor (M5), but is moved down by means

of a cam operated by the drive of the main motor (M1) switched by the pick-up roller down

solenoid (SL1).

The feeding roller and the separation roller make sure that only one sheet of paper is moved to

the feeding path; the paper is then moved as far as the registration roller by the No. 2 registration

roller and the vertical path roller.

The drive of the vertical path roller and the No. 2 registration roller is switched by turning on

and off the vertical path roller clutch (CL3).

The drive of the registration roller comes from the main motor (M1) by way of the registration

roller clutch (CL1). Table 7-103 and Figure 7-103 show the loads in the cassette pick-up assembly

and a conceptual diagram of the electrical parts.

Notation

M1

M5

CL1

CL3

SL1

Name

Main motor

Cassette pick-up motor

Registration roller clutch

Vertical path roller clutch

Pick-up roller down solenoid

Signal

M1D

Note

CL1D*

CL3D*

SL1D*

Terminal on the DC controller

J102-B11

J108

J102-B4

J108-A4

J108-A5

Note: Pulse signal, and cannot be checked for its state (0 or 1) by a meter.

Table 7-103 Loads of the Cassette Pick-Up Assembly