COPYRIGHT © 1999 CANON INC. CANON imageRUNNER 400/330 REV.0 JAN. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

14-169

CHAPTER 14 TROUBLESHOOTING

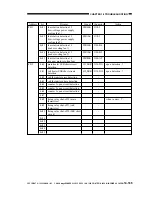

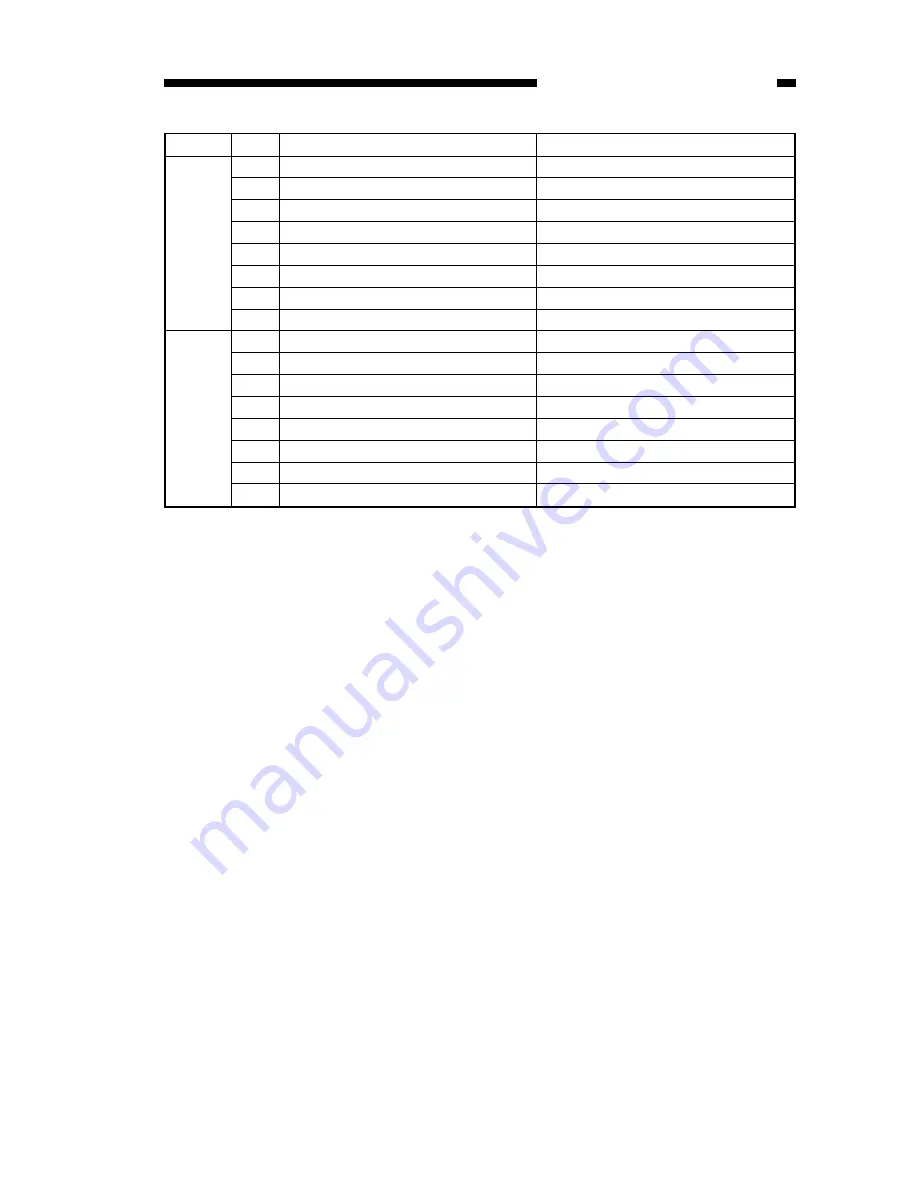

Address

P009

P010

Remarks

when '0', ON.

when '0', ON.

when '1', ON.

when '1', ON.

when '1', ON.

when '1', ON.

when '1', ON.

when '1', ON.

when '1', ON.

when '1', ON.

bit

bit0

bit1

bit2

bit3

bit4

bit5

bit6

bit7

bit0

bit1

bit2

bit3

bit4

bit5

bit6

bit7

Display

not used

not used

not used

not used

not used

not used

LED1 on DADF controller PCB

LED2 on DADF controller PCB

DSW1-8 on DADF controller PCB

DSW1-7 on DADF controller PCB

DSW1-6 on DADF controller PCB

DSW1-5 on DADF controller PCB

DSW1-4 on DADF controller PCB

DSW1-3 on DADF controller PCB

DSW1-2 on DADF controller PCB

DSW1-1 on DADF controller PCB