COPYRIGHT © 1999 CANON INC. CANON imageRUNNER 400/330 REV.0 JAN. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

7-1

CHAPTER 7 PICK-UP/FEEDING SYSTEM

I. OUTLINE OF OPERATIONS

A. Outline

The machine's pick-up/feeding system consists of the upper/lower cassette and the

multifeeder, and it uses a center reference method, in which paper is moved in the middle of the

pick-up path.

Paper picked up from the cassette or the multifeeder is controlled by the registration roller so

that its leading edge matches the image on the photosensitive drum, and is sent to the copy tray

through the transfer, separation, feeding, and fixing assemblies.

As many as 13 sensors are used to monitor the movement of paper, and 11 sensors are used to

detect jams.

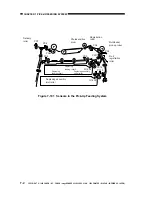

Figure 7-101 shows the arrangement of sensors (input parts), while Figure 7-102 shows

clutches and solenoids (output parts). (These figures are conceptual diagrams, and omit the cassette

drive system.)

Notation

PS3

PS4

PS6

PS7

PS8

PS9

PS10

PS11

PS18

PS19

PS40

Q1604

Q1605

Name

Multifeeder paper sensor

Pre-registration paper sensor

Reversal assembly inlet sensor

Delivery sensor

Duplexing assembly inlet paper

sensor

Re-pick up paper sensor

Horizontal registration sensor

Vertical path paper sensor

Pick-up sensor 1

Pick-up sensor 2

Fixing assembly outlet sensor

Cassette 1 paper sensor

Cassette 2 paper sensor

Signal

PS3S

PS4S

PS6S

PS7S

PS8S

PS9S

PS10S

PS11S

PS18S

PS19S

PS40S

UCSPD

LCSPD

Pin No.*

J108-B17

J108-B11

J106-2

J107-2

J114-B2

J114-B5

J114-B8

J108-B8

J108-A17

J108-A18

J114-A2

J108-A10

J108-A11

* Pin No. of the signal line on the DC controller PCB.

Table 7-101 Sensors in the Pick-Up/Feeding System