COPYRIGHT © 1999 CANON INC. CANON imageRUNNER 400/330 REV.0 JAN. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

9-25

CHAPTER 9 FIXING SYSTEM

11. Adjusting the Lower Fixing Roller

Pressure (nip)

If you have replaced the upper fixing

roller or the lower fixing roller, or fixing faults

occur, make adjustments as follows:

If you are taking measurements when the

fixing roller is cold, wait 15 min after the end

of the wait period, make 20 copies, and then

take measurements.

Taking Measurements

1) Make a single A3 solid black copy, and

feed the output into the multifeeder to

make a solid black copy. Then, set the

resulting output in the multifeeder. (The

output carries two layers of toner.)

2) Select NIP-CHK in service mode

(FUNCTION>FIXING); then, press the

OK key.

3) Check to see that the copier automatically

makes a soiled black copy and delivers it.

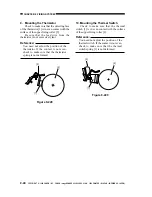

4) Measure the area of the copy where the

toner is shiny.

Figure 9-230

Caution:

a and c are points 10 mm from the ends

of the copy paper.

Dimension

b

a-c

Measurements*

5.5 ± 0.3 [mm]

0.5 mm or less

* Taken when both upper and lower rollers

are fully heated.

Table 9-201

5) If the measurements are not as indicated,

turn the adjusting screw [1] at the rear and

the front of the fixing assembly to make

adjustments.

Figure 9-231

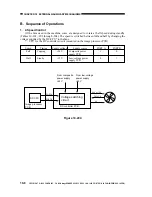

12. Fixing Lower Roller and the Bearing

When replacing the lower roller or the

bearing, apply heat-resisting grease to prevent

caking on the lower fixing roller and the

bearing. (Clean the parts before application.)

A3

Center

of copy

a

b

c

Feeding

direction

[1]