22

Specifications

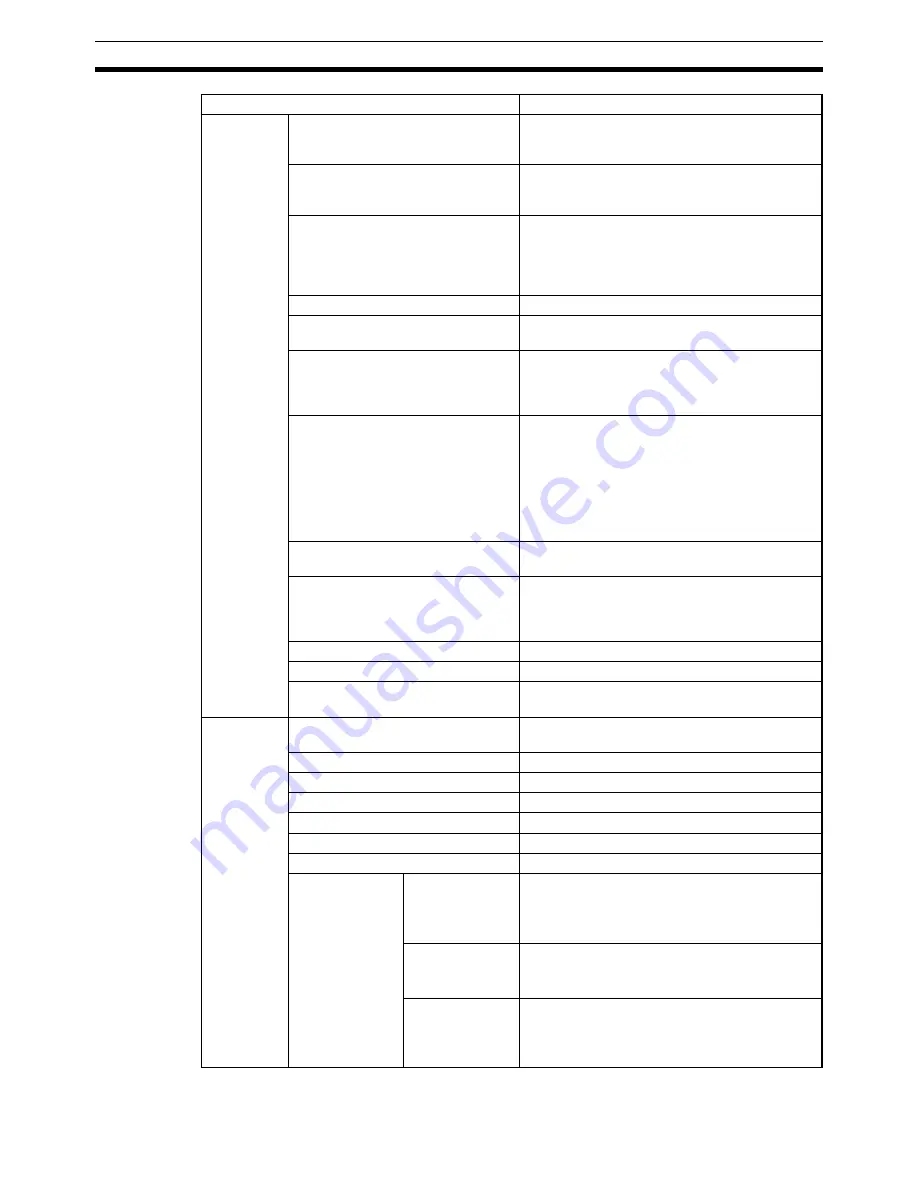

Section 1-5

Automatic

Positioning with linear interpolation

Executes linear interpolation at the specified

interpolation feed rate for up to either two or four

axes simultaneously.

Positioning with circular interpolation

Executes clockwise or counterclockwise 2-axis

circular interpolation at the specified interpolation

feed rate.

Positioning with helical circular

interpolation

Executes clockwise or counterclockwise 2-axis

circular interpolation and 1-axis linear

interpolation (i.e., helical interpolation) at the

specified interpolation feed rate. (Available for

CS1W-MC421 only.)

Traverse function

Executes winding (traverse operation).

Speed control

Moves a maximum of either two or four axes at a

controlled speed.

Interrupt feeding

Moves a specified axis for a fixed amount when a

general input is turned ON. With interrupt feeding,

positioning without an interrupt signal can be

executed.

Switching to Pass Mode

Changes to Pass Mode, in which operations are

executed one by one with no deceleration stop. In

Pass Mode, the interpolation acceleration or

deceleration time of the previous operation can

be specified for the next operation (Pass Mode

time selection). A pass operation for only one axis

can be executed at a fixed acceleration (with a

fixed acceleration mode setting).

Switching to In-position Check OFF

Mode

Starts the next positioning operation without

waiting for the current one to be completed.

Stop-over function

Outputs an M code or a D code while axes are

being moved by a fixed amount (determined by

present position), without stopping the operation.

G codes are also possible for all operations.

Dwell timer

Pauses positioning for a specified time.

Workpiece origin return

Automatically returns to workpiece origin.

Automatic origin return

Automatically returns to reference coordinate

system origin.

Automatic

Cycle start

Executes a specified program from the first block,

or resumes execution of a stopped program.

Single block

Executes the program one block at a time.

Pause

Temporarily halts program execution.

Forced block end

Forcibly ends execution of a block.

Error reset

Clears error status.

M code reset

Resets the M code (for interlock).

Teaching

Creates position data for each task.

Auxiliary

Optional inputs

20 points: Specify input information to be

referenced by special G code.

Of the 20 input points, 4 can be specified as

general-purpose inputs for the MC Unit.

M code

0 to 999

0 to 499: M code for taking interlock

500 to 999: M code not taking interlock

D code (interrupt

code)

0 to 255

Starts a CPU Unit external interrupt task when

positioning is completed or when passing through

a particular position.

Item

Contents

Summary of Contents for CS1W-MC221 -

Page 1: ...Motion Control Units Cat No W359 E1 04 CS1W MC221 V1 421 V1 OPERATION MANUAL ...

Page 2: ...CS1W MC221 V1 421 V1 Motion Control Units Operation Manual Revised February 2008 ...

Page 3: ...iv ...

Page 5: ...vi ...

Page 11: ...xii ...

Page 15: ...xvi ...

Page 19: ...xx ...

Page 27: ...xxviii Conformance to EC Directives 6 ...

Page 133: ...106 Installation Section 2 2 2 2 4 Dimensions CS1W MC421 CS1W MC221 ...

Page 173: ...146 Connecting Peripheral Devices Section 2 7 ...

Page 227: ...200 Command Area Section 3 6 ...

Page 351: ...324 Interface Specifics Section 5 4 ...

Page 513: ...486 Absolute Encoder Interface Specifications Section 9 7 ...

Page 575: ...548 Error Log Section 12 6 ...

Page 589: ...562 Performance Appendix A ...

Page 655: ...628 Control Bit Flag Timing Charts Appendix E ...

Page 683: ...656 Origin Search Patterns Appendix F ...

Page 685: ...658 Encoder Divider Rate and Rotation Speed for OMRON Servo Drivers Appendix G ...