12 Troubleshooting

12 - 40

AC Servomotors/Servo Drives 1S-series with Built-in EtherCAT® Communications User’s Manual (I586)

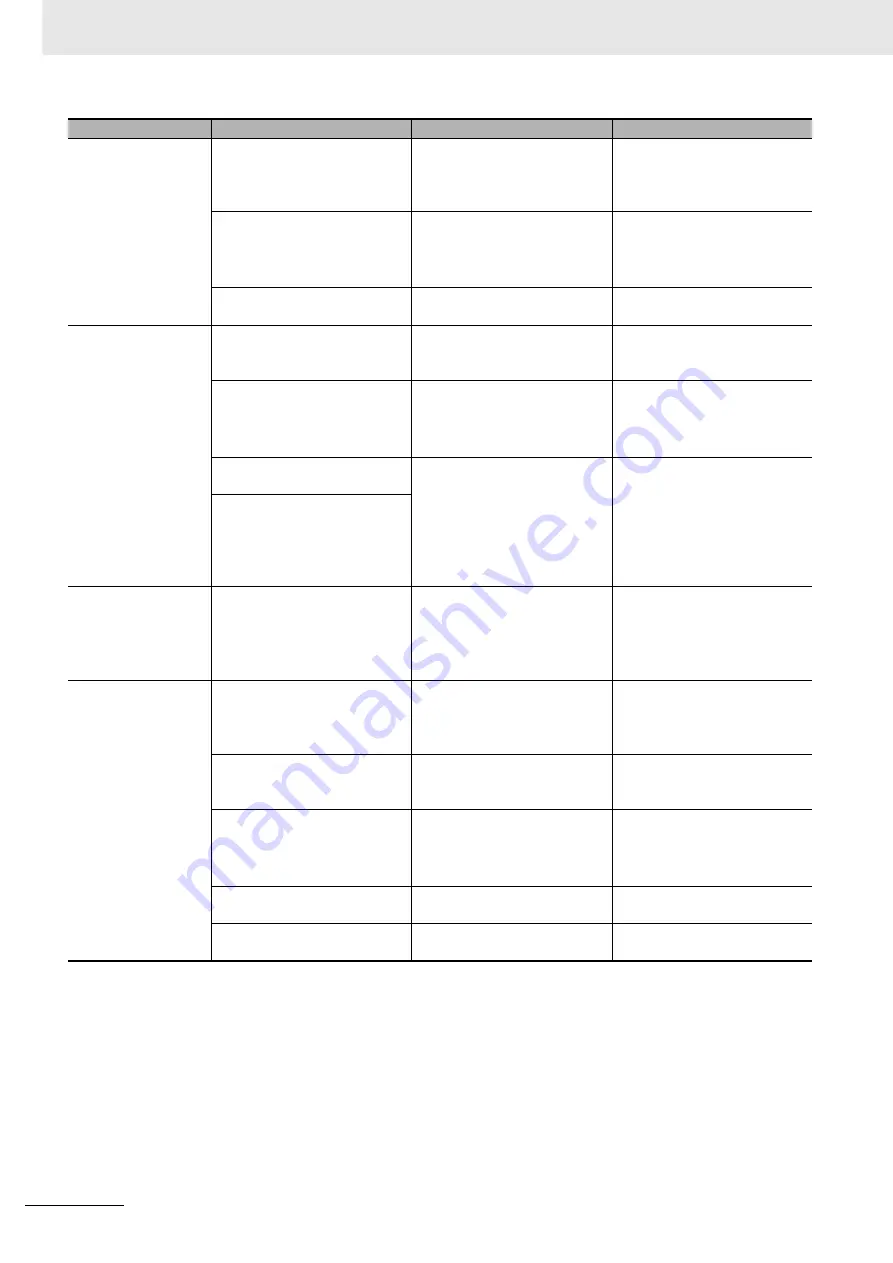

The Servomotor

rotates in the reverse

direction from the

command.

The value set in

Motor Rota-

tion Direction Selection

(3000-01 hex) is incorrect.

Check the value of

Motor

Rotation Direction Selection

.

Change the value of

Motor

Rotation Direction Selection

.

The command given by the

host controller is incorrect.

• The size of the absolute com-

mand is set incorrect.

• The polarity of an incremen-

tal command is set incorrect.

• Check the actual and target

values.

• Check the rotation direction.

The Servomotor power cable is

wired incorrectly.

Check the wiring.

Wire correctly.

When the runaway

detection function is

enabled, the

Servomotor rotates in

the reverse direction

from the command.

The value set in

Motor Rota-

tion Direction Selection

(3000-01 hex) is incorrect.

Check the value of

Motor

Rotation Direction

Selection

.

Change the value of

Motor

Rotation Direction

Selection

.

The command given by the

host controller is incorrect.

• The size of the absolute com-

mand is set incorrect.

• The polarity of an incremen-

tal command is set incorrect.

• Check the actual and target

values.

• Check the rotation direction.

The Servomotor power cable is

wired incorrectly.

Check the wiring.

Wire correctly.

The Servomotor power cable is

wired incorrectly, and condi-

tions under which the runaway

detection function cannot work

are satisfied.

The holding brake

does not work.

Power is supplied to the hold-

ing brake.

Check to see if power is sup-

plied to the holding brake.

• Check the Brake Interlock

Output (BKIR) signal and the

relay circuit.

• Check to see if the holding

brake is worn down.

Motor rotation is

unstable.

The motor power cable or

encoder cable is wired incor-

rectly.

Check the wiring of the motor

power cable’s phases U, V, W

and check the encoder cable’s

wiring.

Wire correctly.

Low rigidity is causing vibration. Measure the vibration fre-

quency of the load.

Enable the damping control.

Set the damping filter fre-

quency.

The load’s moment of inertia

exceeds the Servo Drive’s

allowable value.

Calculate the load inertia.

• Check if manual tuning can

achieve proper adjustment.

• Increase the Servomotor

capacity.

Loose joint and/or large clear-

ance with the machine.

Check the joint with the

machine.

Remove the joint looseness

with the machine.

The load and gain do not

match.

Check the response waveforms

for speed and torque.

Perform the tuning again to sta-

bilize the rotation.

Symptom

Probable cause

Check items

Measures

Содержание R88D-1SN01H-ECT

Страница 17: ...15 CONTENTS AC Servomotors Servo Drives 1S series with Built in EtherCAT Communications User s Manual I586...

Страница 266: ...3 Specifications 3 102 AC Servomotors Servo Drives 1S series with Built in EtherCAT Communications User s Manual I586...

Страница 430: ...8 Safety Function 8 16 AC Servomotors Servo Drives 1S series with Built in EtherCAT Communications User s Manual I586...

Страница 568: ...10 Operation 10 10 AC Servomotors Servo Drives 1S series with Built in EtherCAT Communications User s Manual I586...

Страница 822: ...Appendices A 174 AC Servomotors Servo Drives 1S series with Built in EtherCAT Communications User s Manual I586...

Страница 823: ...AC Servomotors Servo Drives 1S series with Built in EtherCAT Communications User s Manual I586 I 1 I Index...

Страница 826: ...I 4 AC Servomotors Servo Drives 1S series with Built in EtherCAT Communications User s Manual I586 Appendices...

Страница 827: ......