Brivo OEC 715/785/865 Mobile C-Arm X-Ray Product Service Manual

7-12

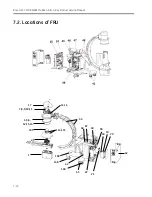

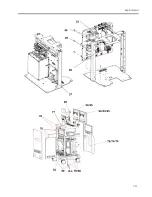

7.3.

Replacement

Electrical circuits inside the equipment use voltages that are capable of Causing serious

injury or death from electrical shock. Use appropriate precautions.

Please use specified fuse.

If the system has power applied, power off the machine and unplug the AC power cord

from the wall outlet.

7.3.1.

General Screws Fastening torque Reference

If no specification in parts replacement procedure, take general screws fastening torque

below as reference.

Hexagon Socket Head Cap Screw:

Material:

Steel;

Property:

8.8;

Finish:

Zinc Plated;

Torque Unit:

Nm;

Tighten Torque Value For Hexagon Socket Head Cap Screw

Thread Specification

M2

M2.5

M3

M4

M5

M6

M8

M10

M12

Torque Value

0.3

0.6

1

2.3

4.6

7.9

19.2

38.4

66.4

Notes

If the material of the thread hole is Aluminum Ally, the tighten torque is the 80% of

the steel tighten torque; if the material of the thread hole is Aluminum Casting,

the tighten torque is the 50% of the steel tighten torque

Cross Recessed Countersunk Head Screws:

Material:

Steel;

Property:

4.8 & 8.8;

Finish:

Zinc Plated;

Torque Unit:

Nm;

Tighten Torque Value For Cross Recessed Countersunk Head Screws

Thread Specification

M2.5

M3

M4

M5

M6

M8

M10

Torque

Value

Property 4.8 0.3

0.4

1

2

3.4

8.4

16.8

Property 8.8 0.6

1

2.3

4.6

7.9

19.2

38.4

Notes

If the material of the thread hole is Aluminum Ally, the tighten torque is the 80% of

the steel tighten torque; if the material of the thread hole is Aluminum Casting, the

tighten torque is the 50% of the steel tighten torque

WARNING

WARNING

WARNING

Summary of Contents for Brivo OEC 715

Page 2: ......

Page 19: ...Chapter1 Introduction and Safety...

Page 41: ...Introduction and Safety 23 46 54 20 18 26...

Page 55: ...Chapter2 System Overview...

Page 137: ...Chapter3 Installation...

Page 212: ...Chapter4 Calibration...

Page 275: ...Brivo OEC 715 785 865 Mobile C Arm X Ray Product Service Manual 4 64...

Page 284: ...Chapter5 Software...

Page 326: ...Software 5 43 2 Click on install to continue 3 Click Next to continue...

Page 335: ...Chapter6 Troubleshooting...

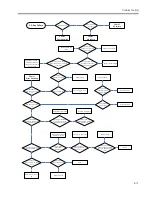

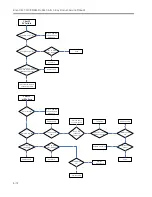

Page 408: ...Chapter7 Replacement...

Page 418: ...Replacement 7 11 166...

Page 488: ...Chapter8 Periodic Maintenance...

Page 502: ...Periodic Maintenance 8 15...

Page 505: ...Chapter9 Technical Reference...

Page 521: ...Technical Reference 9 17 Vertical configuration 1 5m Vertical configuration 1m...

Page 526: ...11 Appendix System Schematics...