Brivo OEC 715/785/865 Mobile C-Arm X-Ray Product Service Manual

4-6

7.

Test the voltage of TP16 on kV control board with multimeter. The voltage should be 3.15

±

0.05V.

Otherwise, adjust R109. Clockwise rotation will decrease the voltage value and anticlockwise will

increase the value.

8.

Test the voltage of TP17 on kV control board with multimeter. The voltage should be 3.15

±

0.05V.

Otherwise, adjust R110. Clockwise rotation will decrease the voltage value and anticlockwise will

increase the value.

9.

Adjust POT6 on MCB board until TP5 (KVO) on MCB is 4.0V

±

0.05V.

10.

Take exposure. Adjust R37 on Filament Driver Board to make sure the mA is 2.1

±

0.2mA.

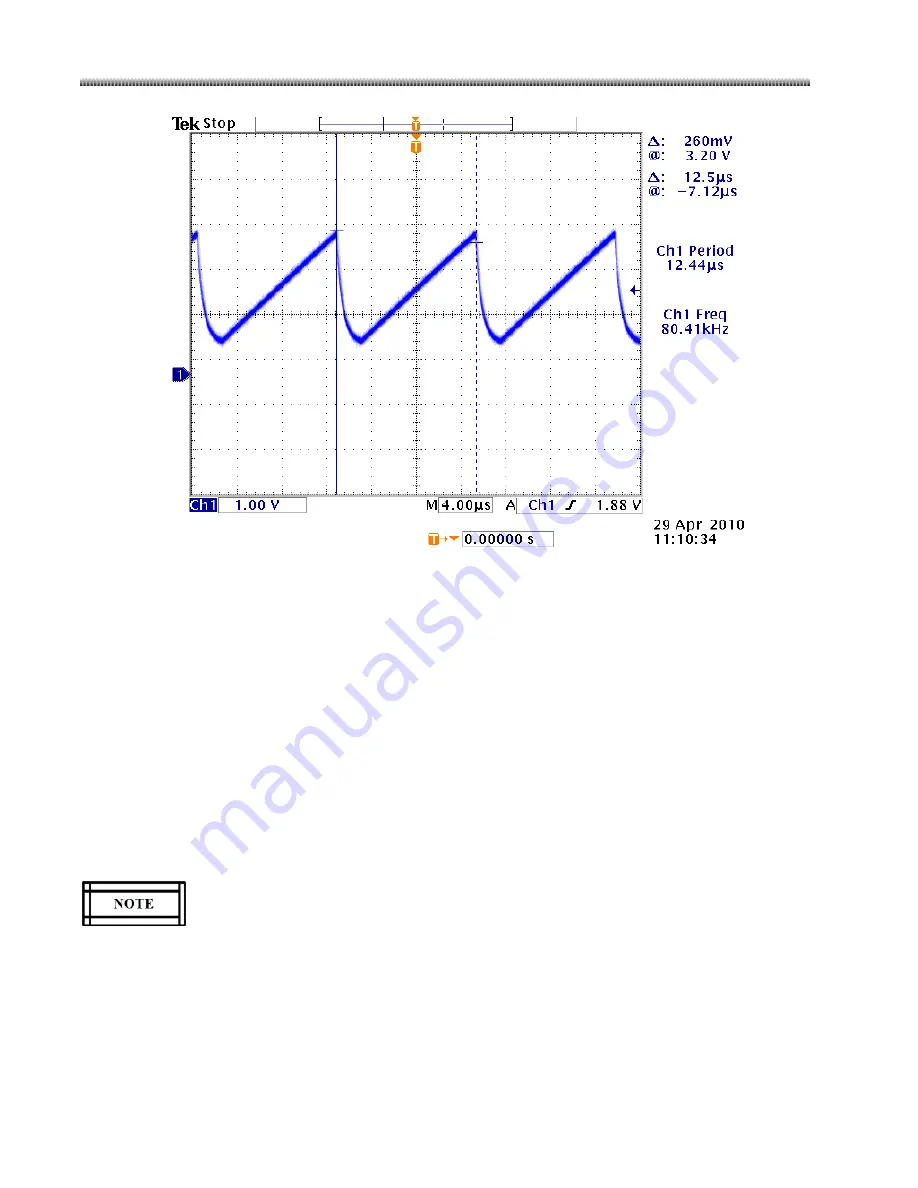

11.

Take exposure and hold on. Measure TP15 on kV Control Board with multimeter. Adjust R50 on kV

control board to make the voltage is 4.0V

±

0.05V. Check that DS1 is lit during exposure.

12.

Restart the system. Check the kV value as the table in 4.2.1. If they are not in specification, adjust

R50 on kV control board or go back to step11.

After the calibration, connect the jumper to J46 on extend board.

13.

After the calibration process completion, remove the extend board and recover the system.

Summary of Contents for Brivo OEC 715

Page 2: ......

Page 19: ...Chapter1 Introduction and Safety...

Page 41: ...Introduction and Safety 23 46 54 20 18 26...

Page 55: ...Chapter2 System Overview...

Page 137: ...Chapter3 Installation...

Page 212: ...Chapter4 Calibration...

Page 275: ...Brivo OEC 715 785 865 Mobile C Arm X Ray Product Service Manual 4 64...

Page 284: ...Chapter5 Software...

Page 326: ...Software 5 43 2 Click on install to continue 3 Click Next to continue...

Page 335: ...Chapter6 Troubleshooting...

Page 408: ...Chapter7 Replacement...

Page 418: ...Replacement 7 11 166...

Page 488: ...Chapter8 Periodic Maintenance...

Page 502: ...Periodic Maintenance 8 15...

Page 505: ...Chapter9 Technical Reference...

Page 521: ...Technical Reference 9 17 Vertical configuration 1 5m Vertical configuration 1m...

Page 526: ...11 Appendix System Schematics...