17 - 67

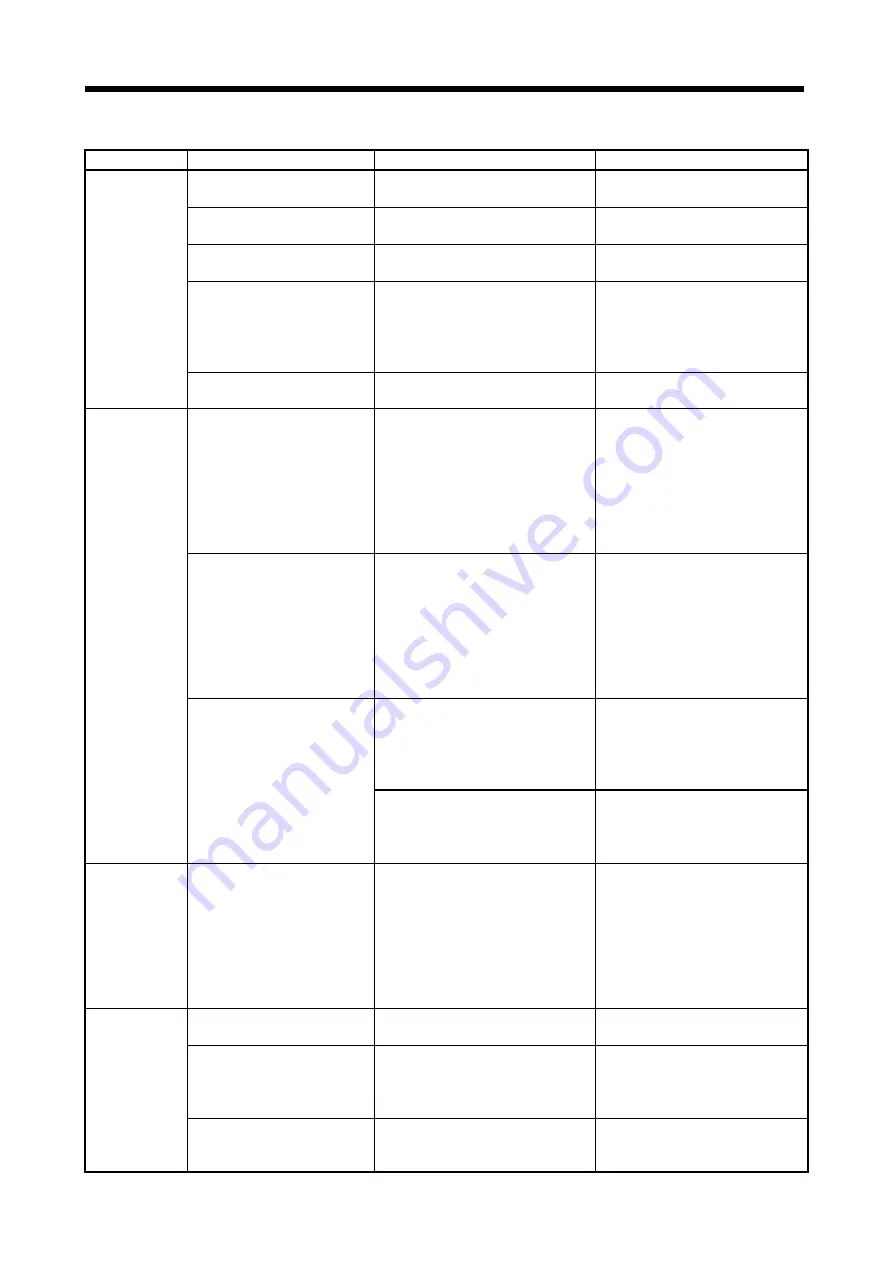

17. SPEED CONTROL OPERATION

Description

Check method

Possible cause

Action

The servo motor

vibrates.

Check the servo motor power

cable.

The output circuit is open phase.

Review the wiring of the servo motor

power cable.

Check if the vibration varies

depending on the speed.

An unbalanced torque of the machine

side is large.

Adjust the balance of the machine

side.

Check the mounting accuracy of

the servo motor and machine.

The eccentricity due to a core gap is

large.

Review the direct accuracy.

Check the load for the servo

motor axis.

The load for the servo motor axis is

large.

Adjust the load for the shaft within the

specifications of the servo motor.

For the shaft permissible load, refer to

"Servo Motor Instruction Manual (Vol.

2)".

Check the vibration from outside. An external vibration propagated to the

servo motor.

Prevent the vibration from the external

vibration source.

The rotation

accuracy is low.

(The rotation

speed is

unstable.)

1. If the servo motor can be driven

safely, repeat acceleration and

deceleration three times or

more to complete auto tuning.

2. Increase the auto tuning

response (parameter

No.PA09). (Except for manual

mode)

1. The servo gain is low.

2. The auto tuning response is low.

Increase the auto tuning response, and

readjust the gain. (Refer to chapter 9.)

Check if the limiting torque (TLC)

is in ON.

1. Check with the external I/O

signal display in the diagnostic

mode.

2. Check with "Input/output I/F

Display" command of "Monitor"

menu on MR Configurator.

An unintended torque limit is enabled.

(When the torque limit is enabled, the

torque limit (TLC) is ON. )

Cancel the torque limit.

Check if the maximum torque

exceeds the torque limit value.

1. Check the "instantaneous

torque" in the status display.

2. Check the torque ripple with

“Graph” command of "Monitor"

menu on MR Configurator .

The maximum torque is insufficient.

1. Shortage of servo capacity.

2. Too large load.

1. Reduce the load by changing the

mass and shape of the workpiece.

2. Reduce the effective load ratio by

increasing acceleration/deceleration

time.

The setting of the torque limit is

incorrect.

(Set with parameter PA11, PA12,

PC35.)

Check the torque limit setting.

Unsteady

vibration at a

stop.

1. If the servo motor can be driven

safely, repeat acceleration and

deceleration three or four times

to complete auto tuning.

2. Increase the auto tuning

response (parameter

No.PA09). (Other than manual

mode)

1. The servo gain is low.

2. The auto tuning response is low.

Increase the auto tuning response, and

readjust the gain. (Refer to chapter 9.)

The servo motor

starts rotating

upon the

power-on of the

servo amplifier,

or the servo

motor starts

rotating upon

servo-on.

Check if the servo-on is turned

ON.

Servo-on has been on at power-on.

Check the controller programs.

For a servo motor with an

electromagnetic brake, check the

timing of releasing the

electromagnetic brake.

1. The sequence of releasing the

electromagnetic brake is incorrect.

2. Failure of power supply for the

electromagnetic brake.

1. Check the sequence of releasing

the electromagnetic brake.

2. Check the power supply for the

electromagnetic brake.

Check the servo motor power

cable.

The output circuit is open phase.

Check the wiring of the servo motor

power cable.

Summary of Contents for Melservo-J3 Series MR-J3-B

Page 19: ...10 MEMO ...

Page 55: ...1 36 1 FUNCTIONS AND CONFIGURATION MEMO ...

Page 61: ...2 6 2 INSTALLATION MEMO ...

Page 179: ...4 58 4 SIGNALS AND WIRING MEMO ...

Page 241: ...5 62 5 OPERATION MEMO ...

Page 357: ...10 16 10 SPECIAL ADJUSTMENT FUNCTIONS MEMO ...

Page 385: ...11 28 11 TROUBLESHOOTING MEMO ...

Page 397: ...12 12 12 OUTLINE DRAWINGS MEMO ...

Page 755: ...17 70 17 SPEED CONTROL OPERATION MEMO ...

Page 793: ...App 38 APPENDIX MEMO ...

Page 799: ...MEMO ...