11 - 26

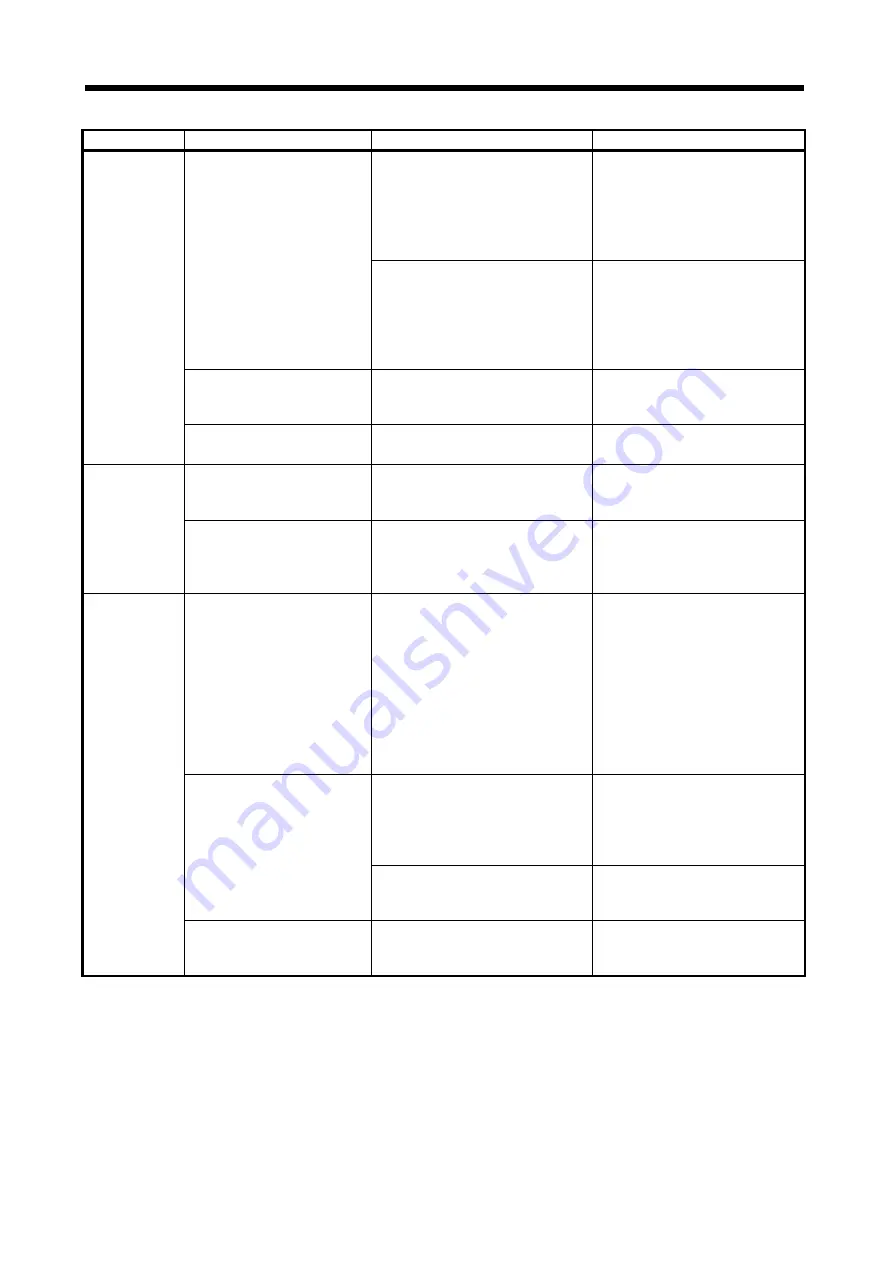

11. TROUBLESHOOTING

Description

Check method

Possible cause

Action

The position

deviates during

operation after

the home

position return.

The input value from the manual

pulse generator MR-HDP01 and

the command position (mm) do

not match.

Wiring or multiplication setting

(parameter No.PA05, manual pulse

generator multiplication 1 (TP1) and

manual pulse generator multiplication 2

(TP2)) of the manual pulse generator is

incorrect.

1. Check the wiring.

2. Check if multiplication setting is set

correctly.

1. Command input pulses are

miscounted by noises.

2. Shielding the command cable is

faulty.

3. The command cable has a contact

failure or disconnected.

Check the shield procedure of the

command cable.

The command from the controller

and the command position of the

amplifier do not match.

Communication command error.

(An unintended command is inputted).

Review the controller programs and

protocol.

(Refer to chapter 3.)

Check the in-position range

(parameter No.PA10).

The in-position range is too large.

Set a narrower in-position range.

In absolute

position detection

system, a

restored position

deviates at power

restoration.

For the geared servo motor,

check the setting of the electronic

gear (parameter No.PA06, PA07).

The reduction ratio is not calculated

correctly.

Review the setting of the reduction

ratio.

For positioning operation after the

home position return, the position

mismatch does not occur.

The maximum speed (3000r/min) at a

power failure was exceeded during

servo amplifier power-off.

Review the machine configuration so

that the servo motor will not rotate at

speed of 3000r/min or higher during

power-off.

Overshoot/

undershoot

occurs.

1. Check the velocity waveform

with “Graph” command of

"Monitor" menu on MR

Configurator, and check if

overshoot/undershoot is

occurring.

2. If the servo motor can be driven

safely, repeat acceleration and

deceleration three times or

more to complete auto tuning.

1. The servo gain is low or too high.

2. The auto tuning response is low or too

high.

Adjust the auto tuning response, and

readjust the gain. (Refer to chapter 9.)

Check if the maximum torque

exceeds the torque limit value.

1. Check the "instantaneous

torque" in the status display.

2. Check the torque ripple with

“Graph” command of "Monitor"

menu on MR Configurator.

The maximum torque is insufficient.

1. Shortage of servo capacity.

2. Too large load.

1. Reduce the load by changing the

mass and shape of work.

2. Reduce the effective load ratio by

increasing acceleration/deceleration

time.

The setting of the torque limit is

incorrect. (Set with parameter

No.PA11/PA12/PC35)

Review the torque limit setting.

Check if there is a backlash on

the machine part.

There is a backlash between the servo

motor and the machine (such as a gear

and coupling).

Adjust the backlash on the coupling

and the machine part.

Summary of Contents for Melservo-J3 Series MR-J3-B

Page 19: ...10 MEMO ...

Page 55: ...1 36 1 FUNCTIONS AND CONFIGURATION MEMO ...

Page 61: ...2 6 2 INSTALLATION MEMO ...

Page 179: ...4 58 4 SIGNALS AND WIRING MEMO ...

Page 241: ...5 62 5 OPERATION MEMO ...

Page 357: ...10 16 10 SPECIAL ADJUSTMENT FUNCTIONS MEMO ...

Page 385: ...11 28 11 TROUBLESHOOTING MEMO ...

Page 397: ...12 12 12 OUTLINE DRAWINGS MEMO ...

Page 755: ...17 70 17 SPEED CONTROL OPERATION MEMO ...

Page 793: ...App 38 APPENDIX MEMO ...

Page 799: ...MEMO ...