54

System Manual – MOVIDRIVE® compact Drive Inverters

2

MOVIDRIVE® compact MCH electronics data

Technical Data and Dimension Drawings

MOVIDRIVE

®

compact

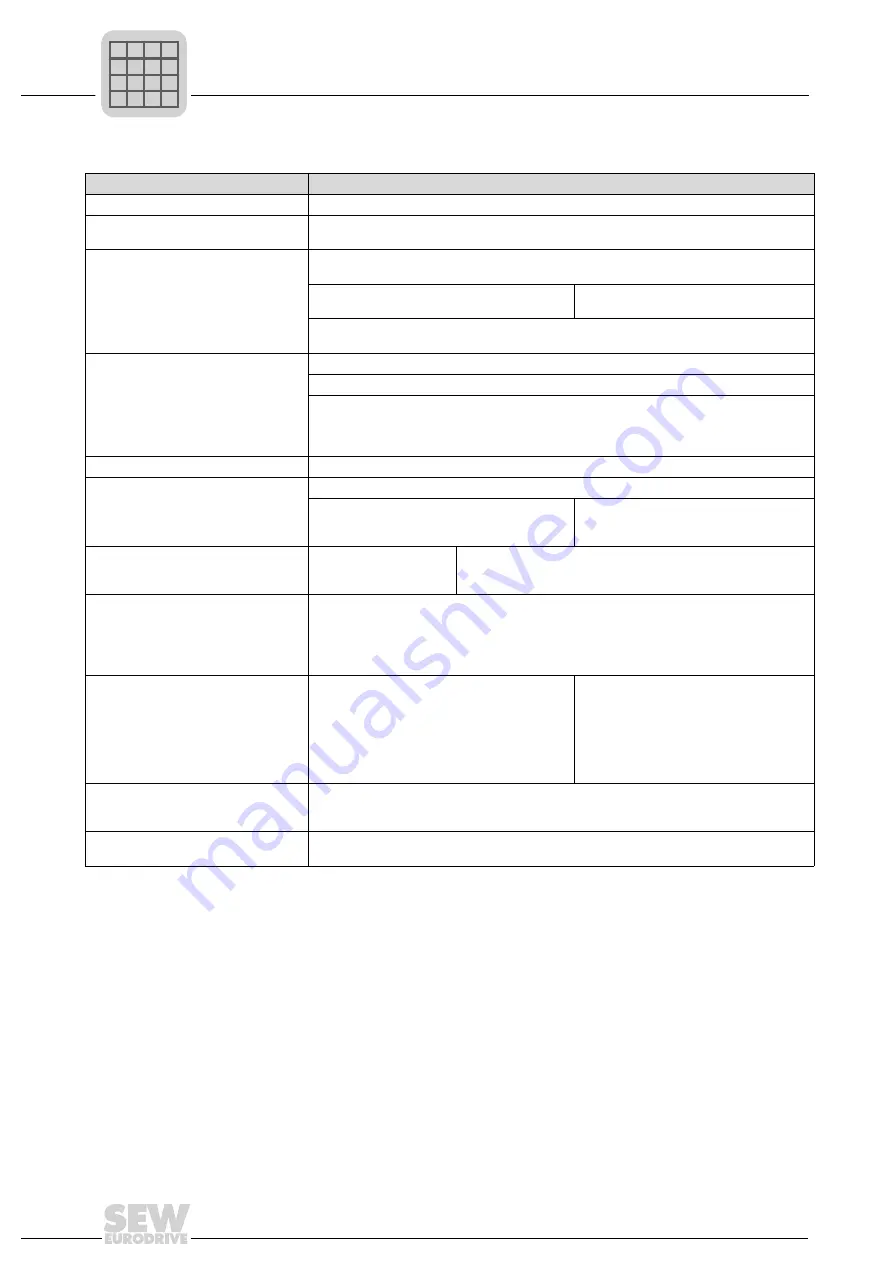

Additional electronics data

Auxiliary voltage output

1)

X11:8

VO24: V

OUT

= DC 24 V, maximum current carrying capacity I

max

= DC 200 mA

Ext. voltage supply

1)

X12:6

VI24: V

IN

= DC 24 V –15 % / +20 % to EN 61131-2

Binary inputs

X11:1...X11:6

Internal resistance

DIØØ...DIØ5: Isolated (optocoupler), PLC-compatible (EN 61131), sampling interval 5 ms

R

i

≈

3 k

Ω

, I

E

≈

10 mA

Signal level

DC (+13 V...+30 V) = "1" = Contact closed

DC (–3 V...+5 V) = "0" = Contact open

Complies with EN 61131

Function

X11:1

X11:2...X11:6

DIØØ: fixed assignment with "/Controller inhibit"

DIØ1...DIØ5: Selection option

→

parameter menu P60_

Binary outputs

1)

X12:1/X12:5

DBØØ/DOØ2: PLC-compatible (EN 61131-2), response time 5 ms

Signal level

"0" = 0 V

"1" = +24 V

Important: Do not apply external voltage!

Function

X12:1

X12:5

DBØØ: With fixed assignment "/Brake", I

max

= DC 150 mA (short-circuit proof,

protected against external voltage up to DC 30 V)

DOØ2: Selection option

→

parameter menu P62_, I

max

= DC 50 mA (short-circuit proof and

protected against external voltage up to DC 30 V)

Analog output

X12:5

AOØ1:

→

Menu P64_, resolution 8 bit, I

max

= DC 20 mA (short-circuit proof)

Relay output

X12:2/3/4

DOØ1: Load capacity of the relay contacts U

max

= DC 30 V, I

max

=DC 800 mA

Function

X12:2

X12:3

X12:4

DOØ1-C: Shared relay contact

DOØ1-NO: Normally open contact

DOØ1-NC: Normally closed contact

Selection option

→

parameter menu P62_

Systembus (SBus)

X10:7/10

X10:8/11

SC11/21: SBus high

SC12/22: SBus low

CAN bus to CAN specification 2.0, parts A and B, transmission

technology to ISO 11898, max. 64 stations, terminating resistor

(120

Ω

) can be activated using DIP switch.

Input motor encoder

1)

X15:

Permitted encoder types:

•

Hiperface encoder

•

sin/cos encoder AC 1 V

SS

•

TTL sensor

Encoder power supply: DC + 12 V, I

max

= DC 180 mA

Output for incremental encoder X14:

simulation or

external encoder input

1)

Output for incremental encoder simulation:

Signal level to RS422

The number of pulses is:

•

1024 pulses/revolution (Hiperface

®

encoder

on X15)

•

as at X15: Motor encoder input (sin/cos

encoder or TTL sensor on X15)

External encoder input (max. 200 kHz):

Permitted encoder types:

•

Hiperface encoder

•

sin/cos encoder AC 1 V

SS

•

TTL sensor

Encoder power supply: DC+12 V,

I

max

= DC 180 mA

Reference terminals

X10:5

X10:9/X11:9/X12:7

X11:7

AGND: Reference potential for analog signals n1 and n2 and terminals X10:1 and X10:6.

DGND: Reference potential for binary signals, system bus (SBus), encoder and resolver.

DCOM: Reference potential for binary inputs X10:9...X10:14 (DIØØ...DIØ5).

Permitted line cross section

Only one core per terminal:

0.20...1.5 mm

2

(AWG 24...16)

Use right-angled crimping pliers with 1.5 mm

2

(AWG 16)

1)

MCH40A (without fieldbus): The unit provides a current of I

max

= DC 400 mA for the DC+24 V outputs (VO24, DBØØ, DOØ2,

encoder supply). If this value is insufficient, a DC 24 V voltage supply must be connected to X10:24 (VI24). This external

DC 24 V voltage supply must be able to provide 50 W continuous power and 100 W peak power (1 s).

MCH41A (with PROFIBUS-DP) or MCH42A (with INTERBUS-LWL): SEW-EURODRIVE recommends that you always

supply these units with DC 24 V at terminal X10:24 (VI24). This external DC 24 V voltage supply must be able to provide 50 W

continuous power and 100 W peak power (1 s).

The DC 24 V outputs X10:16 (VO24), X10:21 (DBØØ) and X10:19 (DOØ2) may be supplied with a total maximum current of

I

max

= DC 400 mA.

P

i

f

kVA

Hz

n

Summary of Contents for MOVIDRIVE compact MCH41A

Page 2: ...SEW EURODRIVE Driving the world...

Page 432: ......