SD20-G Series

262

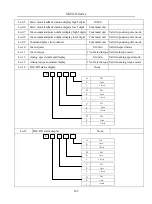

Po303

Position loop feedforward gain

Position

Setting Range

Setting Unit

Mfr’s Value

Effect

0~1000

N/A

0

Immediate effect

Po306

Position filter time constant

Position

Setting Range

Setting Unit

Mfr’s Value

Effect

1~10000

1ms

1

Immediate effect

Position loop gain decides the responsiveness of position control.The bigger setting value is, the higher

gain is, and rigidity is larger. In same frequency instruction pulse, the better following feature of position

instruction is, the lower position error is, and the shorter positioning setting time is, but overlarge setting

value could cause mechanical shack or position overshoot. Internal servo drive uses feedforward

compensation for position control to narrow the positioning time, but the setting value is overlarge, it

may cause mechanical vibration.

If position control instruction changes smoothly, increasing gain can reduce the position following error;

if it does not change smoothly, lower gain can reduce the vibration of system.

B) Speed Loop Gain

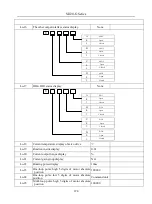

Po101

1

st

Speed loop proportional gain

speed position torque

Setting Range

Setting Unit

Mfr’s Value

Effect

0~30000

0.1Hz

600

Immediate effect

Po102

1

st

Speed loop integral time

speed position torque

Setting Range

Setting Unit

Mfr’s Value

Effect

0~10000

0.1ms

500

Immediate effect

Po103

2

nd

Speed loop proportional gain

speed position torque

Setting Range

Setting Unit

Mfr’s Value

Effect

0~30000

0.1Hz

240

Immediate effect

Po104

2

nd

Speed loop integral time

speed position torque

Setting Range

Setting Unit

Mfr’s Value

Effect

0~30000

0.1ms

1250

Immediate effect

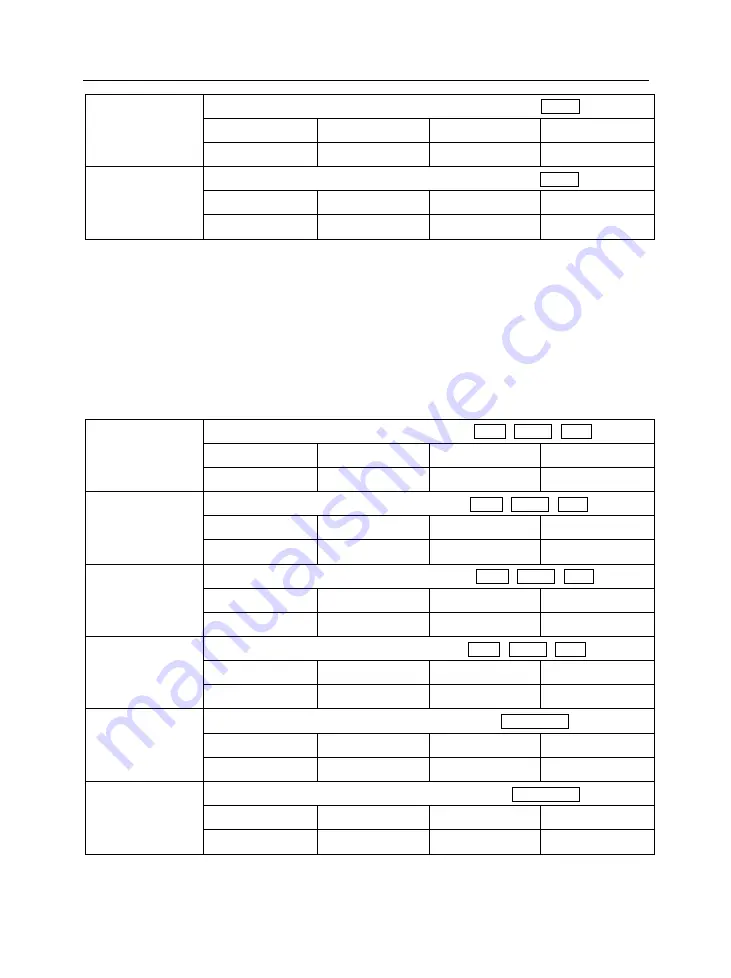

Po105

1

st

Speed loop time constant

speedposition

Setting Range

Setting Unit

Mfr’s Value

Effect

1~20000

0.1ms

1250

Immediate effect

Po106

2

nd

Speed loop filter time constant

speedposition

Setting Range

Setting Unit

Mfr’s Value

Effect

1~20000

0.1ms

—

Immediate effect

Speed loop proportional gain decides the responsiveness of position control. The bigger setting value is,

the higher gain is, but oversize setting could cause mechanical resonance. The frequency in speed mode

Summary of Contents for SD20-G Series

Page 35: ...SD20 G Series 35 M3 structure Fig 3 1 5 Servo drive structure 3...

Page 36: ...SD20 G Series 36 ML3 structure 118 5 5 7 5 93 297 8 223 118 93 0 5 12 5 7 5 4 M4...

Page 38: ...SD20 G Series 38 M4 structure Approx mass 10 365 kg Fig 3 1 7 Servo drive structure 5...

Page 39: ...SD20 G Series 39 M5 structure Approx msaa 11 1Kg Fig 3 1 8 Servo drive structure 6...

Page 40: ...SD20 G Series 40 M6 structure Approx mass 17 4Kg Fig 3 1 9 Servo drive structure 7...

Page 182: ...SD20 G Series 182 Fig 6 4 44SD20E Cam internal frameworkdiagram...