SD20-G Series

104

OFF

OFF

ON

ON

T1

OFF

OFF

OFF

ON

OFF

OFF

ON

OFF

300ms

100ms

Delay time

Delay time

Servo and motor

enable status

Electromagnetic

braking signal

Enable

signal

Braking status

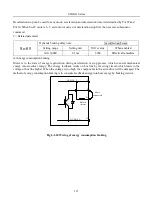

Fig 6-1-4 Electromagnetic brake sequence diagram

Note: after servo enabled is off, T1 is the lower value of So-03 and the time taken by speed arriving to setting

value of So-16.

c)

Power-off brake function

When power-off is detected, make motor in lock state to prevent equipment from falling off.

So-28

Power-off brake

Speed Position Torque

Setting range

Setting unit

Mfr’s value

Effect

0

~

1

N/A

1

Effective Immediate

0:invalid 1:valid

So-29

Power-off brake time

Speed Position Torque

Setting range

Setting unit

Mfr’s value

Effect

500

~

30000

0.1ms

1000

Effective Immediate

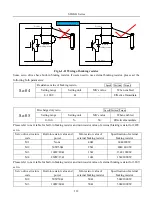

Power-off brake function

Brake DO status

Off

ON

Off

Off

Locked

Unlock brake

So- 29

Internl circuit postpones lock

Off

Off

ON

ON

Power supply

Fig 6-1-5 Powewr-off brake sequence diagram

Summary of Contents for SD20-G Series

Page 35: ...SD20 G Series 35 M3 structure Fig 3 1 5 Servo drive structure 3...

Page 36: ...SD20 G Series 36 ML3 structure 118 5 5 7 5 93 297 8 223 118 93 0 5 12 5 7 5 4 M4...

Page 38: ...SD20 G Series 38 M4 structure Approx mass 10 365 kg Fig 3 1 7 Servo drive structure 5...

Page 39: ...SD20 G Series 39 M5 structure Approx msaa 11 1Kg Fig 3 1 8 Servo drive structure 6...

Page 40: ...SD20 G Series 40 M6 structure Approx mass 17 4Kg Fig 3 1 9 Servo drive structure 7...

Page 182: ...SD20 G Series 182 Fig 6 4 44SD20E Cam internal frameworkdiagram...