SD20-G Series

155

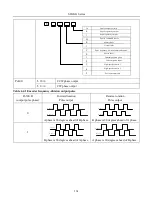

Step

Operation

Description

1

Check machine specifications.

Check the reduction ratio, ball screw lead, and pulley

diameter.

2

Check the encoder resolution of servo

motor.

Check the number of encoder pulse for one revolution.

3

Travel per command pulse

Determine the travel per command pulse from the

command controller

4

Calculate the number of command pulse

per load shaft revolution

Calculate the number of command pulse for turning load

shaft one revolution based on the previously determined

command unit.

5

Calculate the electronic gear ratio.

Use the electronic gear ratio equation to calculate the ratio

6

Set parameters.

Set parameters using the calculated values.

Setting parameters procedure is as below:

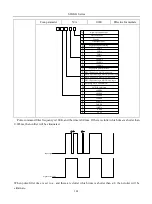

Electric gear ratio

selection

Electric gear

ratio 1

1. Electric gear ratio 1

2. Electric ger ratio 2

3. Terminal selection

Electric gear

ratio 2

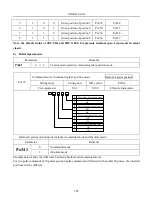

When Po304 and Po346 are not 0, electronic gear ratio equals to Po304/Po305 (Po344/Po346). If Po304

(Po344)=0, pulse numbers of motor rotating a rotation is controlled by Po305 (Po304).

3)

Related parameters

It needs 131072 pulses from servo drive to make a 17bit encoder rotate a rotation (when electronic gear is 1).

①

Function code

Po304

1

st

group electronic gear numerator

Position

Setting range

Setting unit

Mfr’s value

When enabled

0~65535

N/A

0

Effective Immediate

Po305

1

st

electronic gear denominator

Position

Summary of Contents for SD20-G Series

Page 35: ...SD20 G Series 35 M3 structure Fig 3 1 5 Servo drive structure 3...

Page 36: ...SD20 G Series 36 ML3 structure 118 5 5 7 5 93 297 8 223 118 93 0 5 12 5 7 5 4 M4...

Page 38: ...SD20 G Series 38 M4 structure Approx mass 10 365 kg Fig 3 1 7 Servo drive structure 5...

Page 39: ...SD20 G Series 39 M5 structure Approx msaa 11 1Kg Fig 3 1 8 Servo drive structure 6...

Page 40: ...SD20 G Series 40 M6 structure Approx mass 17 4Kg Fig 3 1 9 Servo drive structure 7...

Page 182: ...SD20 G Series 182 Fig 6 4 44SD20E Cam internal frameworkdiagram...