SD20-G Series

180

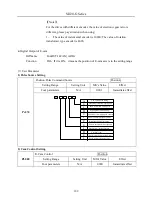

1) Position feedback source setting

Po382

Gantry position feedback source

Position

Setting Range

Setting Unit

Mfr’s value

Effect

0~1

N/A

0

Immediate effect

0

:

high-speed counter 1;

1

:

high-speed counter 2;

2) Feedback ratio setting

Po384

Gantry synchron feedback proportion numerator

Position

Setting Range

Setting Unit

Mfr’s value

Effect

1~2147483647

N/A

10

Immediate effect

Po386

Gantry synchron feedback proportion denominator

Position

Setting Range

Setting Unit

Mfr’s value

Effect

1~2147483647

N/A

10

Immediate effect

3) Gain setting

Po381

Gantry synchron gain

Position

Setting Range

Setting Unit

Mfr’s value

Effect

1~30000

N/A

1

Immediate effect

The value of Po381 cannot be higher than the value of position-loop gain Po301.

4) Alarm output setting

Po383

Gantry synchron alarm pulse

Position

Setting Range

Setting Unit

Mfr’s value

Effect

10~65535

N/A

1000

Immediate effect

Alarm AL-32 given when synchro error is higher than Po383.

(3)

Wiring Instruction

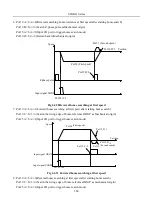

Gantry synchron needs interactive connection of two servo drives, which means that frequency dividing

output of shaft A is connected to pulse input of shaft B, and frequency dividing output of shaft B is

connected to the pulse input of shaft A. Typical wiring diagram shows as below:

Summary of Contents for SD20-G Series

Page 35: ...SD20 G Series 35 M3 structure Fig 3 1 5 Servo drive structure 3...

Page 36: ...SD20 G Series 36 ML3 structure 118 5 5 7 5 93 297 8 223 118 93 0 5 12 5 7 5 4 M4...

Page 38: ...SD20 G Series 38 M4 structure Approx mass 10 365 kg Fig 3 1 7 Servo drive structure 5...

Page 39: ...SD20 G Series 39 M5 structure Approx msaa 11 1Kg Fig 3 1 8 Servo drive structure 6...

Page 40: ...SD20 G Series 40 M6 structure Approx mass 17 4Kg Fig 3 1 9 Servo drive structure 7...

Page 182: ...SD20 G Series 182 Fig 6 4 44SD20E Cam internal frameworkdiagram...