SD20-G Series

131

Note:

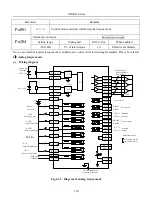

1 represents twisted-pair wires.

2 Servo drive has internal 24 VDC power supply. But external 12~24VDC power supply is recommended.

3 DI1~DI8 are programmable input terminals, and DO1~DO4 are programmable output terminals. Users can

redefine these terminals by parameter.

b)

Related parameters

Parameter

Remarks

Po001

d □ 4

Control mode selection: analog torque mode.

(

1

)

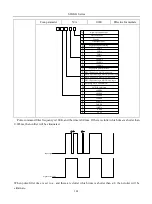

Analog torque command source

Po429

Analog torque command source

Speed Torque

Position

Setting range

Setting unit

Mfr’s value

When enabled

0~1

N/A

1

Effective Immediate

Setting value

Constent

0

Analog command is set by AI1.

1

Analog command is set by AI2.

(

2

)

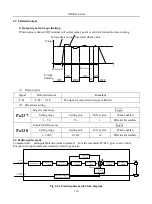

Relationship between analog and torque

Po401

Max torque corresponding to Analog torque

Torque

Setting range

Setting unit

Mfr’s value

When enabled

1~800

1% of rated torque

100

Effective Immediate

Set the torque value when analog voltage is 10V.

The slope equals to the ratio of 10V/setting value of

Po401.

Please refer to the right figure about the mfr’s setting:

10V

-10V

Voltage (V)

Torque N·m

0

Rated torque

Rated torque

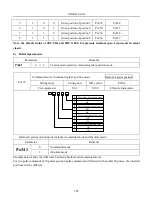

(

3

)

AI2 channel zero drift compensation

Po403

AI2 torque command zero drift compensation

Speed Torque

Position

Setting range

Setting unit

Mfr’s value

When enabled

Summary of Contents for SD20-G Series

Page 35: ...SD20 G Series 35 M3 structure Fig 3 1 5 Servo drive structure 3...

Page 36: ...SD20 G Series 36 ML3 structure 118 5 5 7 5 93 297 8 223 118 93 0 5 12 5 7 5 4 M4...

Page 38: ...SD20 G Series 38 M4 structure Approx mass 10 365 kg Fig 3 1 7 Servo drive structure 5...

Page 39: ...SD20 G Series 39 M5 structure Approx msaa 11 1Kg Fig 3 1 8 Servo drive structure 6...

Page 40: ...SD20 G Series 40 M6 structure Approx mass 17 4Kg Fig 3 1 9 Servo drive structure 7...

Page 182: ...SD20 G Series 182 Fig 6 4 44SD20E Cam internal frameworkdiagram...