SD20-G Series

157

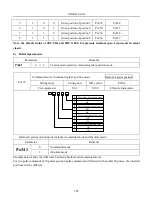

Servo

motor

17 bits encoder

The deceleration

ratio is 1

Pitch is 6mm.

Fig 6-4-18 Setting electronic gear

Step

Operation

Calculation

1

Check machine specifications.

The deceleration ratio is 1:1 and the ball screw lead is 6mm.

2

Check the number of encoder pulses.

17 bits encoder

3

Determine travel per command pulse

The command unit is 1μm.

4

Calculate the number of command

pulse per load revolution

6000μm/1μm=6000

5

Calculate the electronic gear ratio.

B/A=(131072/6000) ×1/1

6

Set parameters.

Po304=8192 Po305=375

6.4.3 Position command filter

For the below situation, position command filter should be selected:

1.

Position command of PC/PLC output is not dealt with by acceleration/deceleration.

2.

The frequency of pulse command is high.

3.

The electronic gear ratio is higher than 10 times.

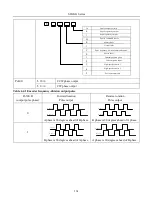

Po306

Position loop filter time constant

Position

Setting range

Setting unit

Mfr’s value

When enabled

1~10000

ms

1

Effective Immediate

Setting position loop filter time constant correctly can make motor rotate smoothly. The parameter does not

affect pulse numbers.

Filter frequency is used to inhibit high-frequency of disturbance pulses. Please do not set this value too low, avoid

inhibiting effective high-frequency pulse command.

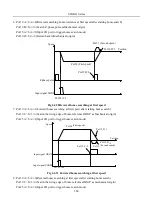

6.4.4 Soft start of position command

Po343

Acceleration/deceleration time in position mode

Position

Setting range

Setting unit

Mfr’s value

When enabled

0~10000

ms

0

Effective Immediate

Increasing the value of Po343 can make motor accelerate or decelerate stability, but response time will be

increased. Otherwise, decreasing the value of Po343 will reduce motor stability.

Actual acceleration time=Po343 X target speed/rated speed

Actual deceleration time=Po345 X target speed/rated speed

Summary of Contents for SD20-G Series

Page 35: ...SD20 G Series 35 M3 structure Fig 3 1 5 Servo drive structure 3...

Page 36: ...SD20 G Series 36 ML3 structure 118 5 5 7 5 93 297 8 223 118 93 0 5 12 5 7 5 4 M4...

Page 38: ...SD20 G Series 38 M4 structure Approx mass 10 365 kg Fig 3 1 7 Servo drive structure 5...

Page 39: ...SD20 G Series 39 M5 structure Approx msaa 11 1Kg Fig 3 1 8 Servo drive structure 6...

Page 40: ...SD20 G Series 40 M6 structure Approx mass 17 4Kg Fig 3 1 9 Servo drive structure 7...

Page 182: ...SD20 G Series 182 Fig 6 4 44SD20E Cam internal frameworkdiagram...