SD20-G Series

58

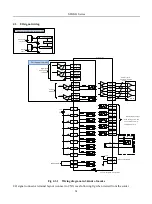

4.2 Encoder wiring

Precaution for encoder wire:

1. Make sure servo drive and motor are grounded reliably, otherwise servo drive may have wrong action.

2. Don’t connect encoder cable to NC terminal.

3. User must consider of cable resistance and distributed capacitance to select cable length.Cable resistance may

cause voltage drop, distributed capacitance will lead to signal attenuation,

4. Encoder cable and power cable must be fixed separately, with at least 30cm distance.

5. If encoder cable is not long enough and needs to connet additional cable, cable shielding layer must be also

connected to ensure reliable shielding and grounding.

4.2.1 Absolute encoder connector terminal layout

CN2 Encoder Connector Terminal Layout is as shown in figure 4-2-1.

1

2

3

4

5

6

7

8

9

Fig 4.2.1 Absolute Encoder Connector Terminal Layout

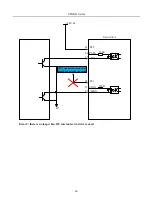

Table 4.2.1 Encoder connector terminal

Terminal

code

Terminal

abbreviation

Signal name

Function

CN2- 1

NC

NO CONNECTION

NO CONNECTION

CN2- 2

VCC

+5V power

+5V power

CN2- 3

PS

PG serial signal

Serial signal

CN2- 4

/PS

PG serial signal

Serial signal

CN2- 5

GND

Grounding

Grounding

CN2- 6

CN2- 7

NC

NO CONNECTION

NO CONNECTION

CN2- 8

NC

NO CONNECTION

NO CONNECTION

CN2- 9

NC

NO CONNECTION

NO CONNECTION

HOUSING

——

(

plug cover

)

Note: 4-core 23 bit incremental encoder has the same terminal layout as absolute encloder.

4-core 23 bit incremental encoder and absolute encoder are communication encoder.

Summary of Contents for SD20-G Series

Page 35: ...SD20 G Series 35 M3 structure Fig 3 1 5 Servo drive structure 3...

Page 36: ...SD20 G Series 36 ML3 structure 118 5 5 7 5 93 297 8 223 118 93 0 5 12 5 7 5 4 M4...

Page 38: ...SD20 G Series 38 M4 structure Approx mass 10 365 kg Fig 3 1 7 Servo drive structure 5...

Page 39: ...SD20 G Series 39 M5 structure Approx msaa 11 1Kg Fig 3 1 8 Servo drive structure 6...

Page 40: ...SD20 G Series 40 M6 structure Approx mass 17 4Kg Fig 3 1 9 Servo drive structure 7...

Page 182: ...SD20 G Series 182 Fig 6 4 44SD20E Cam internal frameworkdiagram...