SD20-G Series

132

0~±5000

1mv

0

Effective Immediate

Analog torque command zero drift

compensation is to eliminate analog

torque command zero drift.

The setting method is as following:

(

1

)

Short-connect AI2 to AGND.

(

2

)

At the mode of analog torque, adjust

Po403 to make Lo-28 to 0.

Please refer to right figure:

Input voltage of analog

channel X(mv)

0

Y(mv)

Zero-drift

Sampling

voltage

Po406

AI automatic zero set

Speed Torque

Setting range

Setting unit

Mfr’s value

When enabled

0~1

N/A

0

Effective Immediate

When AI automatic zero set function is used, please make sure analog input is 0V. If zero drift is too big, servo

drive will trip into AL-21.

When using auto zero set function, make sure analog input is 0V, and set Po406 to 1, after about 3s, zero drift

will auto compensate.

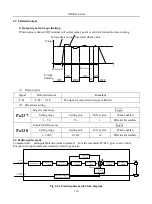

(4)Analog torque command filter

Po405

Analog torque command filter time constant

Torque

Setting range

Setting unit

Mfr’s value

When enabled

1~30000

0.01ms

200

Effective Immediate

This smoothens the speed command by applying a 1st-order filter to the analog speed command input. A value

that is too large, however, will slow down response.

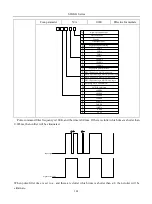

(5)

Upper and lower limit setting of analog torque

The upper and lower limit setting of analog torque is the same with the setting method of analog speed mode,

the setting parameters are different.

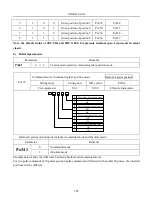

Po434

Torque corresponding to lower limit voltage in torque analog mode

Speed Torque

Position

Setting range

Setting unit

Mfr’s value

When enabled

-1000~1000

0.1%

-1000

Effective Immediate

Po435

Lower limit voltage in torque analog mode

Speed Torque

Position

Setting range

Setting unit

Mfr’s value

When enabled

-1000~1000

0.01V

-1000

Effective Immediate

Po436

Torque corresponding to upper limit voltage in torque analog mode

Speed Torque

Position

Setting range

Setting unit

Mfr’s value

When enabled

Summary of Contents for SD20-G Series

Page 35: ...SD20 G Series 35 M3 structure Fig 3 1 5 Servo drive structure 3...

Page 36: ...SD20 G Series 36 ML3 structure 118 5 5 7 5 93 297 8 223 118 93 0 5 12 5 7 5 4 M4...

Page 38: ...SD20 G Series 38 M4 structure Approx mass 10 365 kg Fig 3 1 7 Servo drive structure 5...

Page 39: ...SD20 G Series 39 M5 structure Approx msaa 11 1Kg Fig 3 1 8 Servo drive structure 6...

Page 40: ...SD20 G Series 40 M6 structure Approx mass 17 4Kg Fig 3 1 9 Servo drive structure 7...

Page 182: ...SD20 G Series 182 Fig 6 4 44SD20E Cam internal frameworkdiagram...