4. STARTUP

4 - 6

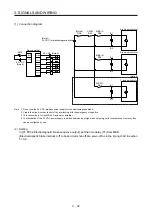

(5) Stop

Turn off the servo-on command after the servo motor has stopped, and then switch the power off.

If any of the following situations occurs, the servo amplifier suspends the running of the servo motor and

brings it to a stop.

Refer to section 3.10 for the servo motor with an electromagnetic brake.

Operation/command

Stopping

condition

Servo system

controller

Servo-off command

The base circuit is shut off and the servo motor coasts.

Ready-off command

The base circuit is shut off and the dynamic brake operates to

bring the servo motor to a stop.

Forced stop command

The servo motor decelerates to a stop with the command. [AL.

E7 Controller forced stop warning] occurs.

Servo amplifier

Alarm occurrence

The servo motor decelerates to a stop with the command. With

some alarms, however, the dynamic brake operates to bring the

servo motor to a stop. (Refer to section 8. (Note))

EM2 (Forced stop 2) off

The servo motor decelerates to a stop with the command. [AL.

E6 Servo forced stop warning] occurs. EM2 has the same device

as EM1 in the torque control mode. Refer to section 3.5 for EM1.

STO (STO1, STO2) off

The base circuit is shut off and the dynamic brake operates to

bring the servo motor to a stop.

Note. Only a list of alarms and warnings is listed in chapter 8. Refer to "MELSERVO-J4 Servo Amplifier

Instruction Manual (Troubleshooting)" for details of alarms and warnings.

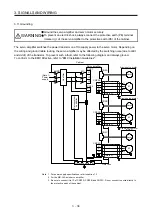

4.3 Switch setting and display of the servo amplifier

Switching to the test operation mode, deactivating control axes, and setting control axis No. are enabled with

switches on the servo amplifier.

On the servo amplifier display (three-digit, seven-segment LED), check the status of communication with the

servo system controller at power-on, and the axis number, and diagnose a malfunction at occurrence of an

alarm.

4.3.1 Switches

WARNING

When switching the axis selection rotary switch (SW1) and auxiliary axis number

setting switch (SW2), use an insulated screw driver. Do not use a metal screw

driver. Touching patterns on electronic boards, lead of electronic parts, etc. may

cause an electric shock.

POINT

Turning "ON (up)" all the control axis setting switches (SW2) enables an

operation mode for manufacturer setting and displays "off". The mode is not

available. Set the control axis setting switches (SW2) correctly according to this

section.

Cycling the main circuit power supply and control circuit power supply enables

the setting of each switch.

Summary of Contents for MR-J4W2-0303B6

Page 39: ...2 INSTALLATION 2 8 MEMO ...

Page 97: ...4 STARTUP 4 20 MEMO ...

Page 181: ...6 NORMAL GAIN ADJUSTMENT 6 28 MEMO ...

Page 235: ...9 DIMENSIONS 9 6 MEMO ...

Page 245: ...10 CHARACTERISTICS 10 10 MEMO ...

Page 309: ...13 USING STO FUNCTION 13 14 MEMO ...

Page 365: ...15 USING A DIRECT DRIVE MOTOR 15 24 MEMO ...

Page 389: ...16 FULLY CLOSED LOOP SYSTEM 16 24 MEMO ...

Page 461: ...17 APPLICATION OF FUNCTIONS 17 72 MEMO ...

Page 556: ...APPENDIX App 41 ...

Page 585: ...MEMO ...