1. FUNCTIONS AND CONFIGURATION

1 - 5

Model MR-J4W2-

22B

44B

77B

1010B

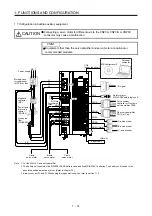

Functional safety

STO (IEC/EN 61800-5-2) (Note 7)

Safety

performance

Standards certified by

CB (Note 12)

EN ISO 13849-1 Category 3 PL e, IEC 61508 SIL 3, EN 62061 SIL CL3, EN 61800-5-2

Response

performance

8 ms or less (STO input off

→

energy shut off)

Test pulse input (STO)

(Note 5)

Test pulse interval: 1 Hz to 25 Hz

Test pulse off time: Up to 1 ms

Mean time to

dangerous failure

(MTTFd)

MTTFd

≥

100 [years] (314a)

Diagnosis converge

(DC)

DC = Medium, 97.6 [%]

Average probability of

dangerous failures

per hour (PFH)

6.4 × 10

-9

[1/h]

Compliance

with global

standards

CE marking

LVD: EN 61800-5-1

EMC: EN 61800-3

MD: EN ISO 13849-1, EN 61800-5-2, EN 62061

UL standard

UL 508C

Structure (IP rating)

Natural cooling, open

(IP20)

Force cooling, open (IP20)

Close mounting

Possible

Ambient

temperature

Operation

0 °C to 55 °C (non-freezing)

Storage

-20 °C to 65 °C (non-freezing)

Environment

Ambient

humidity

Operation

5 %RH to 90 %RH (non-condensing)

Storage

Ambience

Indoors (no direct sunlight), free from corrosive gas, flammable gas, oil mist, dust, and dirt

Altitude

2000 m or less above sea level (Note 13)

Vibration

5.9

m/s

2

or less at 10 Hz to 55 Hz (directions of X, Y and Z axes)

Mass

[kg]

1.5

2.0

Note 1. 0.35 A is the value applicable when all I/O signals are used. The current capacity can be decreased by reducing the number of

I/O points.

2. Reusable regenerative energy corresponds to energy generated under the following conditions.

Rotary servo motor: Regenerative energy is generated when the machine, whose moment of inertia is equivalent to the

permissible charging amount, decelerates from the rated speed to stop.

Linear servo motor: Regenerative energy is generated when the machine, whose mass is equivalent to the permissible

charging amount, decelerates from the maximum speed to stop.

Direct drive motor: Regenerative energy is generated when the machine, whose moment of inertia is equivalent to the

permissible charging amount, decelerates from the rated speed to stop.

3. Moment of inertia when the motor decelerates from the rated speed to stop

Moment of inertia for two axes when two motors decelerate simultaneously

Moment of inertia for each axis when multiple motors do not decelerate simultaneously

The values also apply to the direct drive motor.

4. Mass when the machine decelerates from the maximum speed to stop

The primary-side (coil) mass is included.

Mass for two axes when two motors decelerate simultaneously

Mass for each axis when multiple motors do not decelerate simultaneously

5. Test pulse is a signal which instantaneously turns off a signal to the servo amplifier at a constant period for external circuit to

self-diagnose.

6. The load-side encoder is compatible only with two-wire type communication method. Not compatible with pulse train interface

(A/B/Z-phase differential output type).

7. STO is common for all axes.

8. Fully closed loop control is compatible with the servo amplifiers with software version A3 or later.

Check the software version of the servo amplifier using MR Configurator2.

9. The command communication cycle depends on the controller specifications and the number of axes connected.

10. The scale measurement function is available for the MR-J4W2-_B servo amplifiers of software version A8 or later. Check the

software version of the servo amplifier with MR Configurator2.

11. This value is applicable when a 3-phase power supply is used.

12. The safety level depends on the setting value of [Pr. PF18 STO diagnosis error detection time] and whether STO input

diagnosis by TOFB output is performed or not. For details, refer to the Function column of [Pr. PF18] in section 5.2.6.

13. Follow the restrictions in section 2.7 when using this product at altitude exceeding 1000 m and up to 2000 m above sea level.

Summary of Contents for MR-J4W2-0303B6

Page 39: ...2 INSTALLATION 2 8 MEMO ...

Page 97: ...4 STARTUP 4 20 MEMO ...

Page 181: ...6 NORMAL GAIN ADJUSTMENT 6 28 MEMO ...

Page 235: ...9 DIMENSIONS 9 6 MEMO ...

Page 245: ...10 CHARACTERISTICS 10 10 MEMO ...

Page 309: ...13 USING STO FUNCTION 13 14 MEMO ...

Page 365: ...15 USING A DIRECT DRIVE MOTOR 15 24 MEMO ...

Page 389: ...16 FULLY CLOSED LOOP SYSTEM 16 24 MEMO ...

Page 461: ...17 APPLICATION OF FUNCTIONS 17 72 MEMO ...

Page 556: ...APPENDIX App 41 ...

Page 585: ...MEMO ...