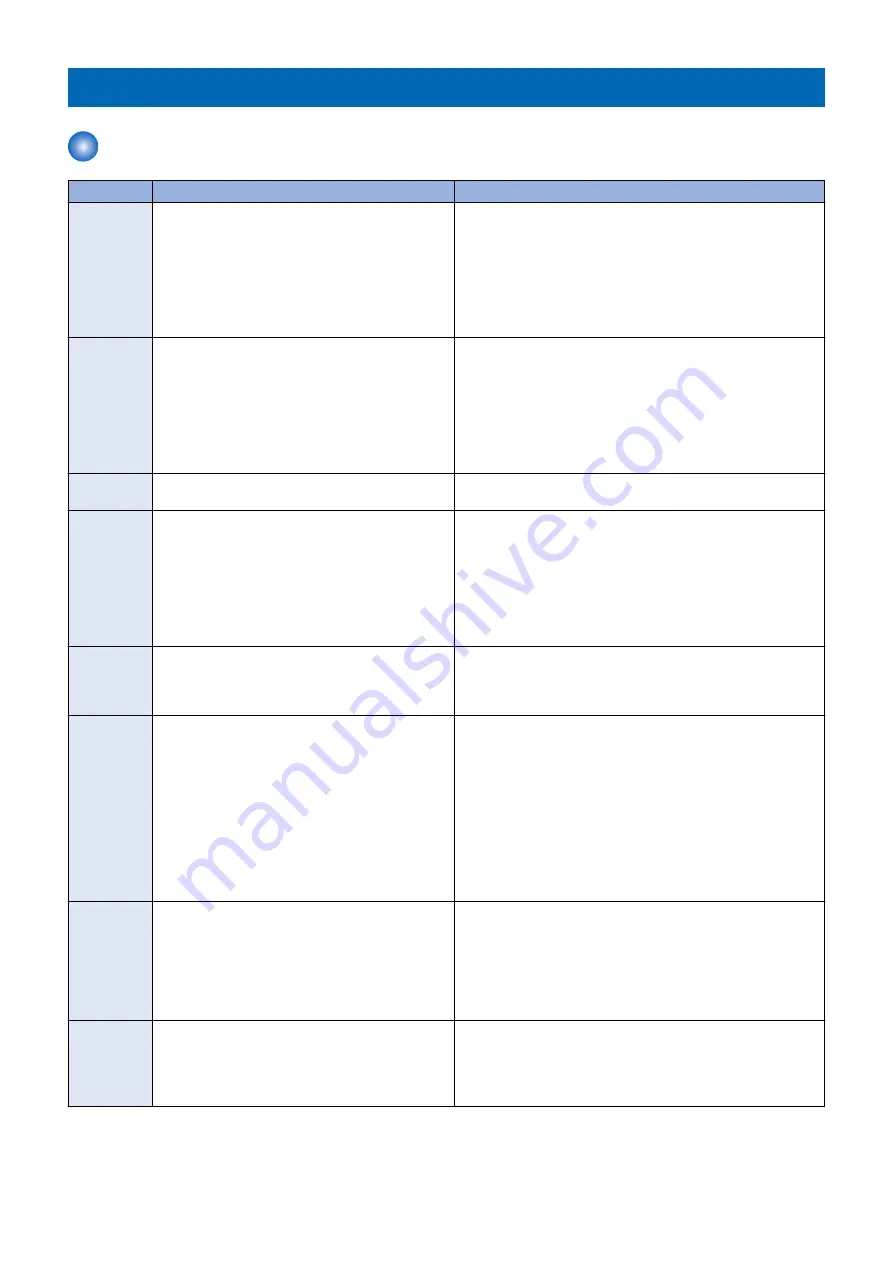

Jam Code

Jam Type

Type

Overview of detection

Check items (in arbitrary order)

Delay

A delay jam occurs when a sensor was not turned ON

although a specified period of time had passed after

the start of detection by the sensor.

• Remaining paper at the upstream of the target sensor

• Soiling on the target sensor

• Displacement of the target sensor position

• Failure of the target sensor

• Soiling (grease)/deterioration/failure of a drive motor located

upstream of the target sensor

• Soiling (paper dust)/deterioration/failure of a drive roller lo-

cated upstream of the target sensor

Stationary

A stationary jam occurs when a sensor was not turned

OFF although a specified period of time had passed

after the sensor was turned ON.

• Remaining paper near the target sensor

• Soiling on the target sensor

• Displacement of the target sensor position

• Failure of the target sensor

• Soiling (grease)/deterioration/failure of a drive motor located

upstream of the target sensor

• Soiling (paper dust)/deterioration/failure of a drive roller lo-

cated upstream of the target sensor

Door open

A door open jam occurs when a sensor detected door

open during printing operation.

• Door open during printing

Sequence

A sequence jam occurs when there was an error in

sensor detection signal at printing operation se-

quence.

Since the jam may occur due to sporadic noise with

software of each equipment or communication line

(interruption of communication), failure of the part is

not the cause of the jam. After the jam is removed, the

machine works.

• Opening/closing of the door

• Turning OFF and then ON the power

• Error near the target sensor (soiling/displacement/failure of

the sensor, error in harness/open circuit of harness, soiling

(grease)/deterioration/failure of a drive motor, or soiling (pa-

per dust)/deterioration/failure of a drive roller)

Power-on

A power-on jam occurs when a sensor detected ON

state at power-on.

• Remaining paper in the machine

• Soiling on the target sensor

• Failure of the target sensor

• Foreign matter on the target sensor (paper dust, paper lint)

Error avoid-

ance

An error avoidance jam occurs when an error in the

machine (excluding parts failure) was detected.

Printing operation is suspended to avoid error occur-

rence by error code; therefore, parts failure is not the

cause of the jam.

After the jam is removed, the machine works.

If it is due to parts failure, an error code instead of the

error avoidance jam is displayed on UI and printing

operation is suspended. In such case, service tech-

nician should perform remedial work for the error

code.

• Opening/closing of the door after jam removal

• Turning OFF and then ON the power after jam removal

Size error

A size error jam occurs when the difference between

the paper length detected by the Cassette Guide

Plate/specified on the Control Panel and the length

measured by the Registration Sensor is out of the

specified range.

• Difference in paper size

• Wrong paper size setting

• Error in the Document Size Sensor (soiling/displacement/

failure of the sensor)

• Error in the Paper Size Detection Unit (failure of mechanical

structure for size detection, failure of the Guide Plate, or fail-

ure of the Cassette Size Switch)

Different me-

dia

A different media jam occurs when the paper type

specified from a PC or the Control Panel differed from

the one detected by the sensor.

• Difference in paper type

• Wrong paper type setting

• Error in the Transparency Sensor (soiling/displacement/fail-

ure of the sensor)

• Soiling on the Reflection Plate of the Transparency Sensor

7. Error/Jam/Alarm

617

Summary of Contents for imageRUNNER ADVANCE C3330 Series

Page 1: ...Revision 7 0 imageRUNNER ADVANCE C3330 C3325 C3320 Series Service Manual ...

Page 18: ...Product Overview 1 Product Lineup 7 Features 11 Specifications 17 Parts Name 26 ...

Page 518: ...Error Jam Alarm 7 Overview 507 Error Code 511 Jam Code 617 Alarm Code 624 ...

Page 1020: ...9 Installation 1008 ...

Page 1022: ...2 Perform steps 3 to 5 in each cassette 9 Installation 1010 ...

Page 1024: ...5 6 Checking the Contents Cassette Feeding Unit 1x 3x 2x 1x 9 Installation 1012 ...

Page 1027: ...3 4 NOTE The removed cover will be used in step 6 5 2x 2x 9 Installation 1015 ...

Page 1046: ...When the Kit Is Not Used 1 2 Close the Cassette 2 When the Kit Is Used 1 9 Installation 1034 ...

Page 1068: ... Removing the Covers 1 2x 2 1x 9 Installation 1056 ...

Page 1070: ...3 1x 1x 9 Installation 1058 ...

Page 1083: ...6 7 TP M4x8 2x 2x 9 Installation 1071 ...

Page 1084: ...When Installing the USB Keyboard 1 Cap Cover Wire Saddle 9 Installation 1072 ...

Page 1129: ...9 2x 10 2x 11 9 Installation 1117 ...

Page 1135: ...Remove the covers 1 ws 2x 2 1x 9 Installation 1123 ...

Page 1140: ...2 2x 3 Connect the power plug to the outlet 4 Turn ON the power switch 9 Installation 1128 ...

Page 1176: ... A 2x Installing the Covers 1 1x 2 2x 9 Installation 1164 ...

Page 1190: ...14 Install the Cable Guide to the HDD Frame 4 Hooks 1 Boss 9 Installation 1178 ...