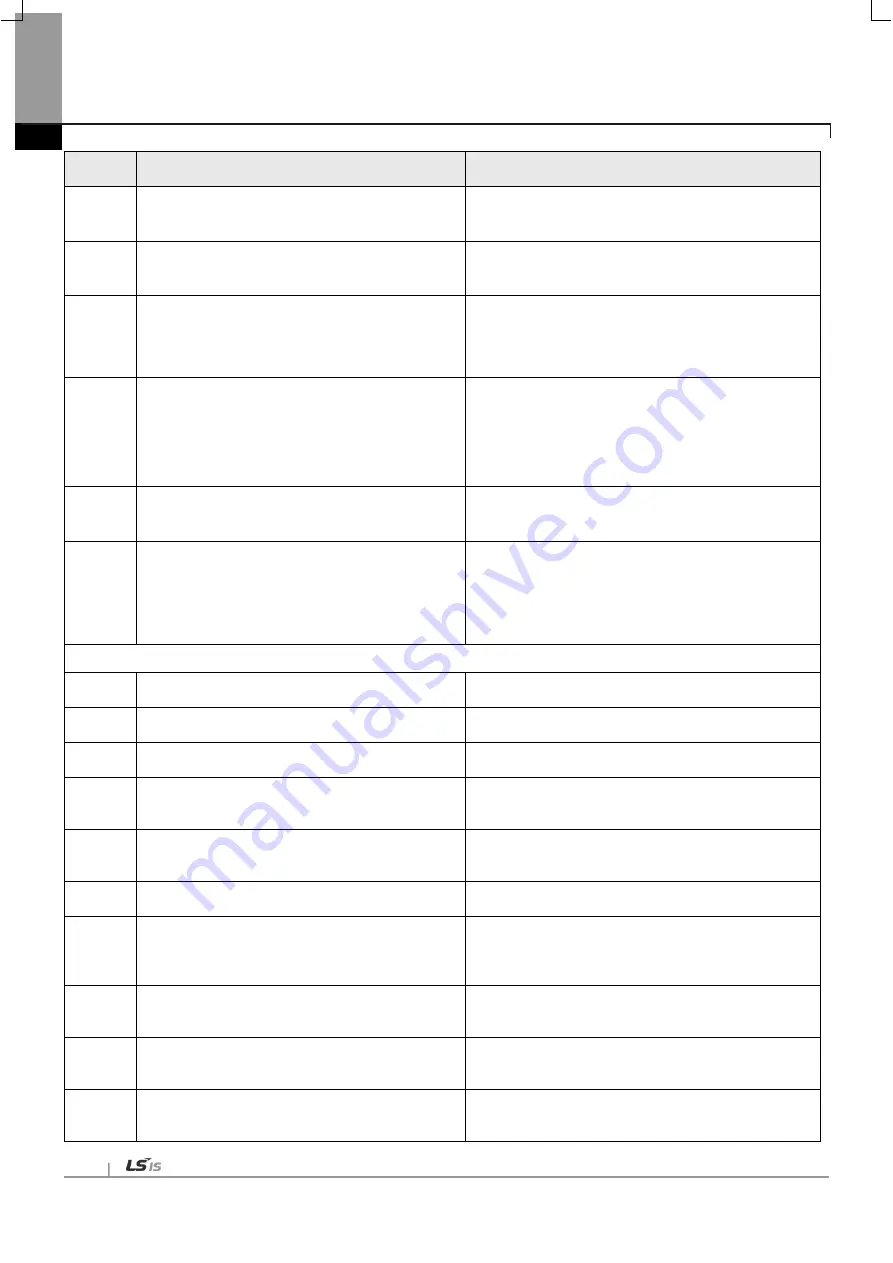

Appendix 1 Positioning Error Information & Solutions

Error

Code

Error Description

Solutions

597

There is no r esponse of the servo driver on

“servo parameter EEPROM save” command.

Check if servo driver is normal or not.

598

The axis for

“

Servo parameter EEPROM

save

”

is not connected now.

It can execute “Servo parameter EEPROM save”

command only for currently connected axis.

599

Unable to carry out other commands during

“Servo parameter write” or “Servo parameter

EEPRO save”

Execute other commands after completing “Servo

parameter write” or “Servo parameter EEPROM

save”.

600

“Abort” arises during “servo parameter read”

command

Check if parameter is readable or parameter

number and setting data is within range.

Sometimes you can’t read parameter according to

servo driver status.

601

There is no r esponse of the servo driver on

“servo parameter read” command.

Check if servo driver is normal or not.

602

It is not possible to execute the “Servo

parameter read/write” or “Servo parameter

save” command in the state that servo

parameter read command is executing.

Execute command when servo parameter read

command is completed.

701

Not possible to carry out CAM command in the

state of in operation.

Execute CAM command when main axis is not

operating.

702

Not possible to carry out CAM command in the

state of M Code ON

Execute CAM command after set M Code OFF

from commanding axis with MOF.

703

Not possible to carry out CAM command in the

state that servo is OFF.

Execute CAM command when Servo On signal is

“ON.”

704

Error of setting main/subordinate axis from

CAM command.

Set main axis for CAM command as other axis

besides its command axis from connecting axis.

Set parameters are 1axis through 8axis.

706

Error of CAM block setting from CAM

command.

Execute CAM command after set a CAM block

from CAM command as bigger than 1 and

smaller than 8.

707

Error for CAM data of appointed block from

CAM command.

Execute CAM command after set right data for

appointed block from CAM command.

708

The speed of subordinate axis from CAM

command cannot exceed its speed limit.

Set lower speed for main axis so that speed

of subordinate axis from CAM data which is

calculated by subordinate position would not

exceed its speed limit.

709

For CAM command, in case main axis is

encoder, main axis unit f CAM data should be

pulse.

When you set the main axis of CAM data as

encoder, set the unit of main axis of CAM block as

pulse.

710

Movement position per control cycle is out of

main axis range of CAM data because high

speed of main axis of CAM command.

Operate with lower speed of main axis.

711

Data area setting value (block size and no. of

block) of Variable Data Read/Write command

is out of range.

Set the block size and no. of block for [block size X

no. of block] to be 1~128.

A1-14

Summary of Contents for XBF-PN04B

Page 1: ...Programmable Logic Controller Positioning Module EtherCAT XGB Series XBF PN04B XBF PN08B ...

Page 626: ...Chapter 9 Functions BPS37 setup RS232 and PC connection BPS37 option board LED 9 193 ...

Page 796: ...Appendix3 Dimension A3 1 Appendix 3 Dimension Appendix 3 1 Dimension of XBF PN04B PN08B ...