352

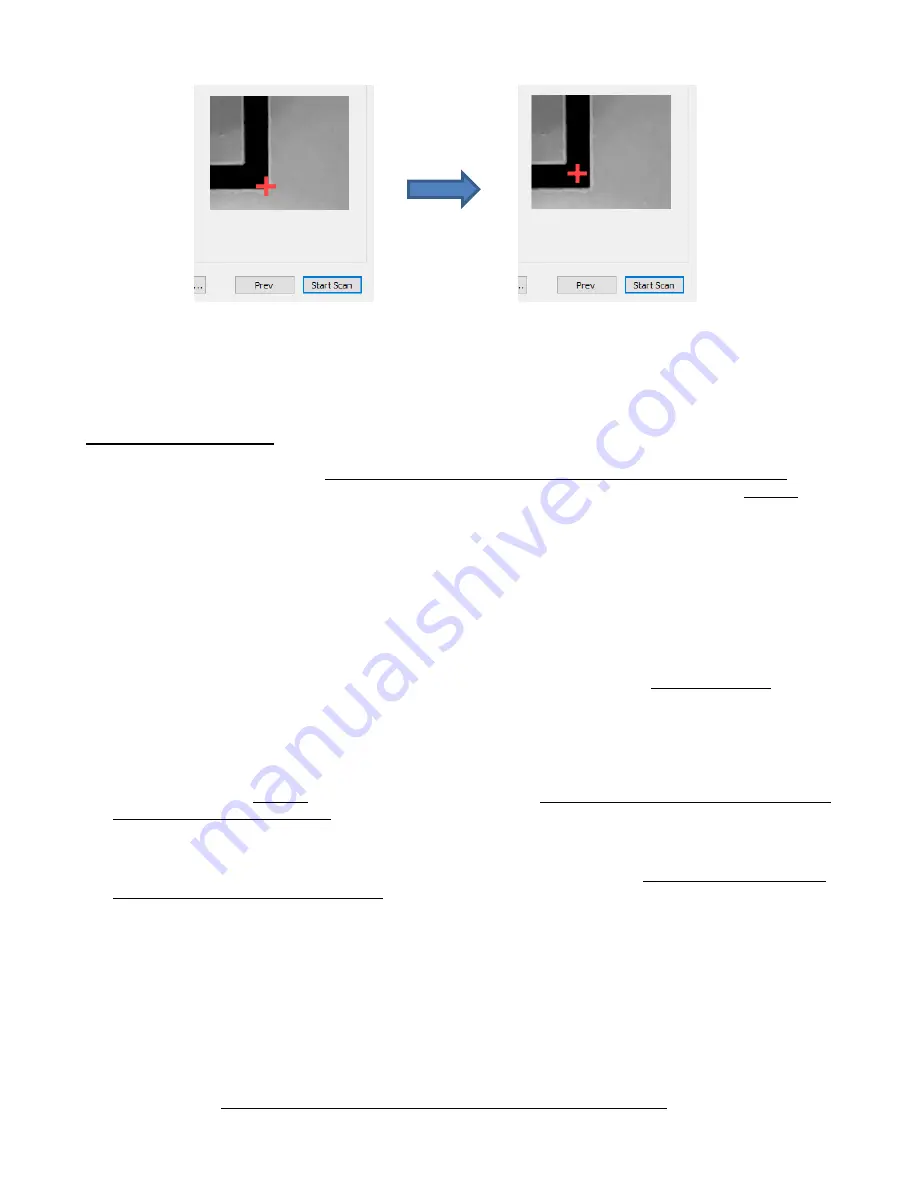

(11) The camera will now identify the lower mark, then the upper right mark, and finally the upper left mark

and then cut out the shapes.

11.06 Print and Cut Tips

•

When tracing imported images, the trace lines will not necessarily be perfectly aligned with the image. This

can result in tiny bits of white appearing in certain spots, suggesting the PNC wasn’t accurate. Zoom in

close on the image so that you can see the trace line following the outline of the image. Look at the same

spots where the cut didn’t follow the image perfectly. This could be the cause of the inaccurate PNC. There

are three ways of handling this situation:

Retrace the imported image, using a lower

Contrast

and/or

Smooth

setting to get a tighter fit of the

trace line to the original graphic (refer to

Section 7.03

).

Use

Path Editing

to move the trace lines to more closely fit the original graphic (refer to

Section 8.10.2.

Create an inset line to use for cutting instead of the original trace line (refer to

Section 8.05

).

•

If a PNC is not precise and the cause is not the alignment of the trace lines, then check the settings

you’re

using. Cutting too deeply into the cutting mat can cause a certain amount of drag on the mat, leading to

errors, especially in applications with many shapes to cut. Also, make sure the pinch wheels, underside of

the cutting mat, and the grit shafts are clean and free of any adhesive.

•

If you wish to use

Landscape

mode for your print and cut applications, then change the

Orientation

on the

Document

Panel

and under

File>Print Setup

to

Landscape

and orient the printout the correct way on the

cutting mat. There is no need to modify the camera calibrations. Currently,

however,

Landscape

mode does

NOT work for PNC on the Force.

•

Faster

Cut and Up Speeds

can be used when cutting thinner materials. For example, you should be able to

use 30 and 30 with simple designs on thin paper. For regular cardstock, you might be able to use 25 and

25. For thicker cardstock, stick with 20 and 20. It also depends on the design. Very precise cutting around

a printed image will need slower speeds than a large contour cut, such as the tag around the cow shown in

Section 17.01. On the other hand, if the mat is moving numerous times, in and out of the cutter, a slight

shifting can occur, especially at higher speeds. So, print and cuts with lots of images will need slower

Cut

and

Up

Speeds

.

•

If you are using PNC in your business and need faster cutting, Francisco Ulloa developed a method

whereby he aligns the mat with the right-side endcap on the Force and designs his files so that all shapes

cut counter-clockwise. This causes the skewing force on the mat to be countered by the presence of the

endcap, keeping the mat straight. He has been able to use maximum

CS

for many of his PNC applications.

Thank you, Francisco! (Note: To change the path direction on an SVG file in C3, refer to

Section 2.02.10

.

To change the path direction within the original design program, refer to

Sections 4.02.1-4.02.5

and the

Quick Guide

table in

Section 4.04.3

).

•

Remember that the calibration of the

Offset

is specific to the particular blade holder and blade type being

used. Thus, if you change, the calibration should be checked and tweaked, as needed.

Summary of Contents for KNK Force

Page 306: ...306...