AR-BC320 SETTING AND ADJUSTMENTS 8 - 27

(Note for performing the color balance adjustment (Auto

adjustment))

1) The print engine section must be properly adjusted.

2) CCD gamma adjustment must be properly adjusted.

3) When setting the color patch image (adjustment pattern)

paper on the original table, place 5 sheets of white paper on

the color patch image paper.

4) Be sure to use the specified color paper.

Before execution of the copy quality check and the copy quality

adjustment, be sure to execute the following corrections forcibly to

set the image forming section to the optimum state.

• Execute the process correction forcibly. (SIM 44-6)

• Execute the half-tone image correction forcibly. (SIM 44-26)

a. Outline

The color balance adjustment (auto adjustment) is the automatic

adjustment of cyan, magenta, yellow, and black copy density with

SIM 46-24 or user program.

There are following two modes of auto color balance adjustment:

1) Auto color balance adjustment by the serviceman (with SIM

46-24)

2) Auto color balance adjustment by the user (with the user pro-

gram) (The color balance target becomes the service target.)

The auto color balance adjustment by the user is provided in

order to reduce the number of service calls.

If the copy color balance is shifted by some reason, the user

performs the color balance adjustment to correct it.

If, however, there is a basic problem in the machine, or if the

machine environment is changed largely, this function does

not serve as an effective means.

While the automatic color balance adjustment by the service-

man allows adjustment even when the machine environment

is changed largely, providing normal color balance. If there is a

basic problem in the machine, repair it and adjust to provide

normal color balance.

The above points must be fully understood for proper operation.

When this adjustment is performed, the color balance adjust-

ment of all the copy modes are changed.

b. Adjustment procedure

(Auto color balance adjustment by the serviceman)

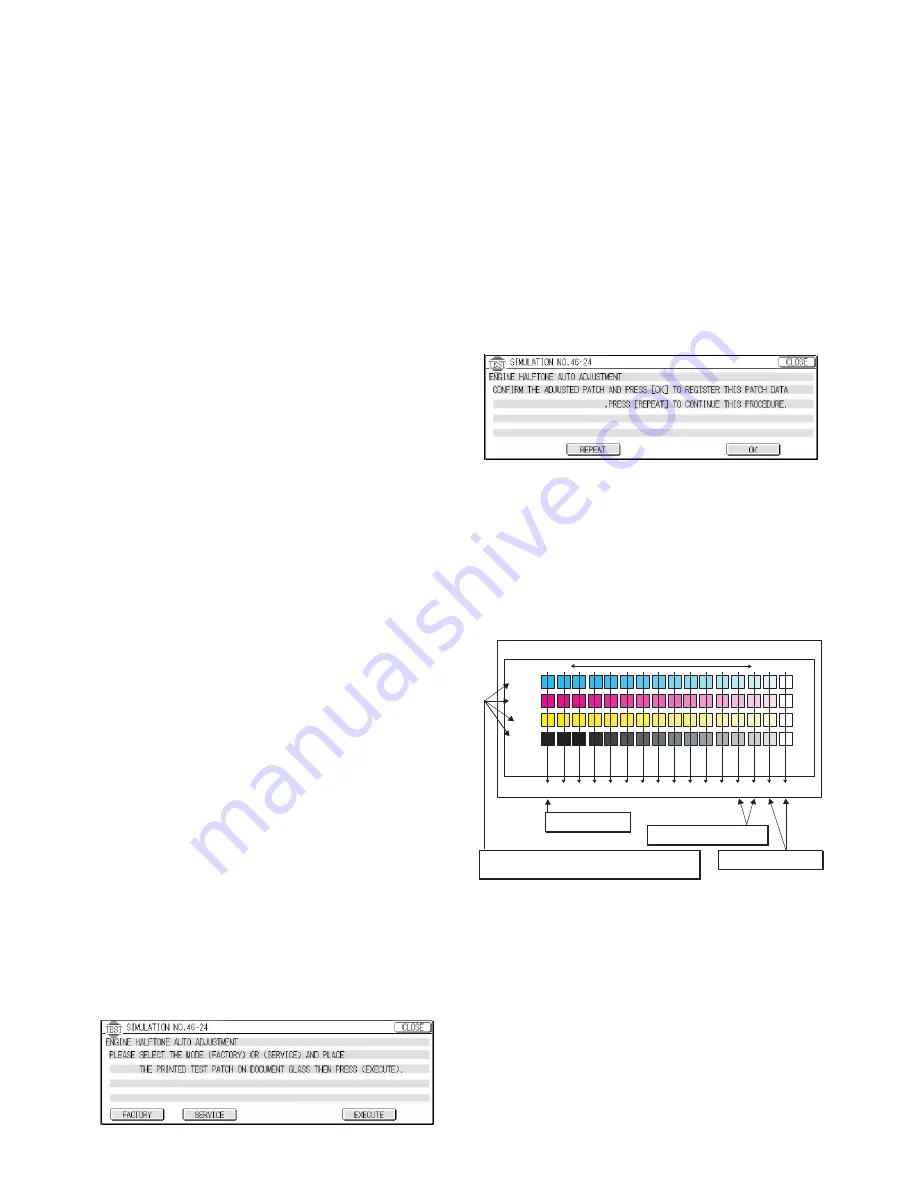

1) Enter the SIM 46-24 mode.

2) Press the [EXECUTE] key.

(A3 or 11 x 17 paper is automatically selected.)

The color patch image (adjustment pattern) is printed.

3) Set the color patch image (adjustment pattern) printed in proce-

dure 2) on the original table so that the dark density side of the

color patch image comes to the left side. Place 5 sheets of white

paper on the color patch image (adjustment pattern) paper.

4) Press the FACTORY key on the operation panel and press the

[EXECUTE] key.

The copy color balance adjustment (step 1) is automatically

performed, and the color balance check patch image is

printed. Wait for a while until the operation menu of procedure

5) is displayed.

When the color balance is customized by the manual color

balance (SIM 46-21) according to the user's request and then

the color balance is registered as the service target by SIM 63-

7, select the service target in order to adjust to that color bal-

ance.

Note: (Descriptions on the factory and the service key button in

the color balance automatic adjustment menu)

There are two kinds of gamma targets for the color balance

automatic adjustment: factory and service.

The factory key button and the service key button are used

to select between them.

Factory target gamma: Standard color balance (Fixed)

Service target gamma: Color balance can be customized

according to the user request. (Variable)

When shipping from the factory, the service target gamma

data are same as the factory target gamma data.

Both are set to the standard color balance gamma.

In the service target, a customized color balance can be

registered with SIM 63-7. In the factory target, it cannot be

changed.

5) Press the OK key on the operation panel.

The initial setup of half tone image correction is performed

according to this adjustment data.

Note: When OK key is pressed, initial setup of half-tone image

correction is started. During this operation, "Copy Quality is

being adjusted" is displayed. It takes several minutes to

complete this operation.

After completion of this operation, "Please quit this mode" is

displayed.

Do not cancel the simulation until "Please quit this mode" is

displayed.

6) Check that the color balance check patch image printed at last

is within the specified range shown below.

The print density should vary gradually from the lower density to

the higher density without reversion of changing direction.

The density level of each color should be almost the same.

It is acceptable for patch B not to be copied.

Patch A is not copied.

Use SIM 46-21 to print the color balance adjustment sheet and

compare each process (CMY) black patch color balance and the

black patch. This allows a correct check on the color balance

adjustment result.

If the color balance of each process (CMY) black patch in A to O is

near the black patch referring to the patch, it is judged that the

color balance has been correctly adjusted.

High density

Low density

Fig. 1 PG image

Max

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

C

M

Y

Bk

1) The max. density

section is not blurred.

3) Patch for each of C, M, Y, BK

• The patch density is identical between patches or not reversed.

• The patch density is changed gradually.

2) Patch C or D of each of Y, C, M,

and BK is very slightly copied.

Patches A and B of each of Y,

M, C, and BK are not copied.

Summary of Contents for AR-BC320

Page 340: ...Memo ...

Page 341: ...Memo ...