Hot Gas Path Inspection — Reassembly Procedures

Inspection and Maintenance — GEK 107048

HGP-R-7

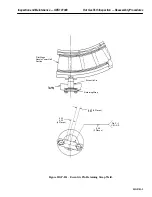

seal strip with the notch facing in. Appropriately stake both seals. See Figures HGP-R.3 and

HGP-R.4.

4. Lift the nozzle and diaphragm segment on its hook fit and slide it along to its proper position.

Install nozzle segments from each horizontal joint to the center of the casing. For those nozzle

segments with thermocouple tubes protruding, insure that enough clearance is available to allow

the segments to be rolled in without damaging the tubes. Each segment and diaphragm weighs

approximately 35 pounds.

Note:

Nozzle segment radial locating pins should be installed after each seg-

ment is moved into position.

5. Apply a light coat of anti-seize compound to all radial retaining pins.

Note:

Prior to installing the radial retaining pin threaded access plugs, clean

the plug threads in the retaining pin hole. This will assist in making

reassembly of access plug easier.

6. Install the retaining pins as each nozzle segment is installed, where plugs are used to hold the re-

taining pins install the access plug so that it just bottoms on the retaining pin. Tighten the access

plug against the retaining pin and stake each plug at four (4) places on the edge of the threads.

7. Where pins are secured in place by holding plates, lockplates are to be used to lock the hex head

bolts.

Operation 3 — How to Install Wheelspace Thermocouples in Lower Half Second and Third

Stage Nozzle Segments

Note:

The removable type thermocouples are located in segments 10 and 15

in the second stage nozzle and segments 11 and 14 in the third stage

nozzle. There are two thermocouples per segment.

Refer to the second and third stage nozzle arrangement drawings in the

Parts Lists and Drawings Volume of this Service Manual for details if

needed.

1. Prior to installing the wheelspace thermocouples, test the thermocouples to insure they are opera-

tional. This can be done by applying a small amount of heat to the tip and reading the output on

a temperature meter.

Note:

The assembled length of the engaged portion of the thermocouple is

stamped on the turbine casing adjacent to the thermocouple tubing in-

stallation hole. This dimension may be used for reference when install-

ing the thermocouples. The reference dimension is from the top swage-

lok ferrell to the tip of the thermocouple.

2. Install the wheelspace thermocouples through the installation tubing in the turbine casing into

the second stage nozzle segment numbers 10 and 15 (two per segment).

3. Install the wheelspace thermocouples through the installation tubing in the turbine casing into

the third stage nozzle segment numbers 11 and 14 (two per segment).

Summary of Contents for MS6001B

Page 2: ...Gas Turbine Inspection and Maintenance GEK 107048 I 2 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 4: ...Inspection and Maintenance Note THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 13: ...INSERT TAB INTRODUCTION ...

Page 14: ......

Page 25: ...INSERT TAB STANDARD PRACTICES ...

Page 26: ......

Page 87: ...INSERT TAB AUXILIARY CONTROLS SYSTEMS MAINTENANCE ...

Page 88: ......

Page 133: ...INSERT TAB SCHEDULED TURBINE MAINTENACE ...

Page 134: ......

Page 157: ...INSERT TAB COMBUSTION INSPECTION ...

Page 158: ......

Page 239: ...INSERT TAB HOT GAS PATH INSPECTION ...

Page 240: ......

Page 313: ...INSERT TAB MAJOR INSPECTION ...

Page 314: ......

Page 316: ...Inspection and Maintenance GEK 107048 Major Inspection 2 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 363: ...INSERT TAB MAINTENANCE FORMS ...

Page 364: ......