Combustion Inspection — Inspection Procedures

Inspection and Maintenance — GEK 107048

CI-I-7

**WARNING**

Cleaning solutions are extremely caustic. Wear pro-

tective clothing, gloves and face shield to prevent con-

tact with skin or eyes. If solution contacts skin or eyes,

irrigate thoroughly with clean water and immediately

obtain medical aid.

CAUTION

Depending on the cleaning solution, a rinse solution is fre-

quently required. Follow the manufacturer’s recommen-

dations for cleaning solution being used.

4. Remove the parts from the cleaning solution, and spray with water and steam to knock off loosened

carbon.

5. Rinse the parts, and coat them with either clean fuel oil or light machine oil.

6. Visually inspect all parts, keeping in mind that the contact surfaces of the fuel nozzle parts are ma-

chined to a fine finish so the flow rates of fuel oil or gas and atomizing air through the nozzle as-

sembly will be within specified limits. When inspecting parts, make sure there are no dents, burrs

or nicks on any surfaces which will result in an interference on reassembly. These types of defects

could affect fuel or air flow.

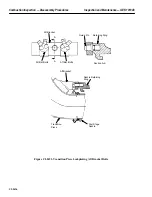

Special attention should be given to the condition of the swirl slots in the fuel nozzle pilot, and

the surfaces with which the nozzle pilot are in contact. If the swirl slots show any indication of

crushing, galling or erosion, or if the surfaces with which they are in contact are not flat and

smooth, the parts must be replaced.

CAUTION

Do not attempt to remachine damaged parts. This can

cause irregular fuel flow, erratic combustion system oper-

ation, and subsequent turbine damage.

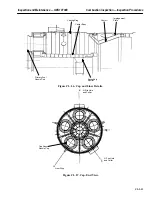

7. Inspect the outer gas swirl tip for wear at the area normally in contact with the combustion liner

cap/collar. If wear in this area is 0.030 inch or more, contact your General Electric Company Field

Service Representative for information concerning repair of the outer gas swirl tip diameter.

8. Inspect the outer tip assembly to determine if parts have been adversely affected by erosion. In-

spect the condition of the gas fuel holes in the gas swirl tip assembly. They should be sharp, not

rounded or burred. If the inlet edges of the gas holes have eroded or have been rounded or nicked,

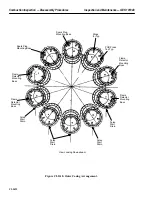

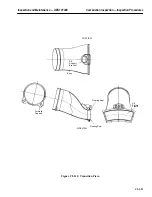

they will affect the flow test. Figure CI-I.3 shows the components of the typical fuel nozzle.

Summary of Contents for MS6001B

Page 2: ...Gas Turbine Inspection and Maintenance GEK 107048 I 2 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 4: ...Inspection and Maintenance Note THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 13: ...INSERT TAB INTRODUCTION ...

Page 14: ......

Page 25: ...INSERT TAB STANDARD PRACTICES ...

Page 26: ......

Page 87: ...INSERT TAB AUXILIARY CONTROLS SYSTEMS MAINTENANCE ...

Page 88: ......

Page 133: ...INSERT TAB SCHEDULED TURBINE MAINTENACE ...

Page 134: ......

Page 157: ...INSERT TAB COMBUSTION INSPECTION ...

Page 158: ......

Page 239: ...INSERT TAB HOT GAS PATH INSPECTION ...

Page 240: ......

Page 313: ...INSERT TAB MAJOR INSPECTION ...

Page 314: ......

Page 316: ...Inspection and Maintenance GEK 107048 Major Inspection 2 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 363: ...INSERT TAB MAINTENANCE FORMS ...

Page 364: ......