Combustion Inspection — Disassembly Procedures

Inspection and Maintenance — GEK 107048

CI-D-19

**WARNING**

Each combustion outer casing weighs approximately

550 pounds and should be rigged accordingly to sup-

port this weight prior to start of disassembly of the out-

er combustion casings.

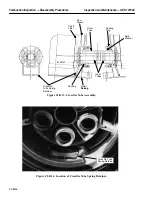

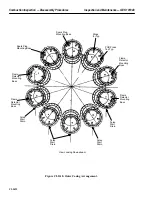

1. Starting with the number 10 combustion casing, rig the casing to the lifting means to support the

weight. Unbolt the casing from the compressor discharge casing bulkhead. See Figure CI-D.18.

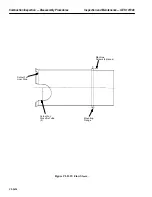

2. Carefully, using the rigging attached, work the combustion casing outward until the flow sleeve

clears the bulkhead. Lift the casing clear of the unit.

3. Set and block the outer casing on wood or heavy cardboard so that no damage is done to the flow

sleeve.

4. Repeat step 2, 3 and 4 for combustion casings 1, 2, 3, 7, 8 and 9.

5. Rig number 4 combustion casing to the lifting means. Attach a comealong to the casing to act as

a restraint to keep the casing from swinging when it clears the compressor discharge casing bulk-

head.

6. Unbolt the casing from the compressor discharge bulkhead and using the rigging attached, care-

fully work the combustion casing outward until the flow sleeve clears the bulkhead. Lift the cas-

ing clear of the unit.

7. Set and block the outer casing on wood or heavy cardboard so that no damage is done to the flow

sleeve.

8. Repeat steps 6, 7 and 8 for combustion casings number 5 and 6.

9. Remove and discard all used gaskets.

10. Clean all hardware and mating flange surfaces. Bag and identify bolting for reassembly.

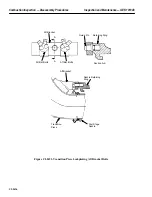

11. Remove the 4 machine screws locating the flow sleeve in the outer casing. See Figure CI-D.19.

12. Slide the flow sleeve aft until it clears the outer casing.

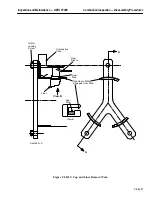

Operation 16 — How to Remove the Transition Pieces

Note:

Before disassembling the transition pieces, clearance measurements

may be taken between the transition piece face and the first stage

nozzle. These measurements, if taken, can be recorded on form PGS/

GT-FF-6408. A special go — no/go gauge is available for this gap mea-

surement.

Note:

Depending on which turbine casing access hand hole ports are avail-

able, (see Operation 18) the first transition piece to be removed can be

Summary of Contents for MS6001B

Page 2: ...Gas Turbine Inspection and Maintenance GEK 107048 I 2 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 4: ...Inspection and Maintenance Note THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 13: ...INSERT TAB INTRODUCTION ...

Page 14: ......

Page 25: ...INSERT TAB STANDARD PRACTICES ...

Page 26: ......

Page 87: ...INSERT TAB AUXILIARY CONTROLS SYSTEMS MAINTENANCE ...

Page 88: ......

Page 133: ...INSERT TAB SCHEDULED TURBINE MAINTENACE ...

Page 134: ......

Page 157: ...INSERT TAB COMBUSTION INSPECTION ...

Page 158: ......

Page 239: ...INSERT TAB HOT GAS PATH INSPECTION ...

Page 240: ......

Page 313: ...INSERT TAB MAJOR INSPECTION ...

Page 314: ......

Page 316: ...Inspection and Maintenance GEK 107048 Major Inspection 2 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 363: ...INSERT TAB MAINTENANCE FORMS ...

Page 364: ......