Inspection and Maintenance

Introduction

I–3

It must be recognized that the foregoing estimated outage requirements can be used for estimating mainte-

nance cycles, however, these numbers will vary depending upon the many factors which establish the op-

erating conditions for a specific installation. The inspection cycles will vary depending upon fuel, duty

cycle and maintenance philosophy of the owner. The inspection manhours will vary depending upon pre-

planning, availability of parts, productivity, weather conditions, union regulations, supervision, etc.

Precise estimates of the outage duration resource requirements and costs associated with the inspection

of a specific installation may be obtained from your GE Company Apparatus and Engineering Services

Operation Representative.

Good maintenance planning for minimum down-time requires the availability of replacement parts, ei-

ther new or previously repaired, that can be exchanged with existing parts. The exchanged parts can then

be repaired without extending the down-time.

To ensure optimum performance of the gas turbine, the minimum stock of spare parts should be able to

support the service inspection. A predetermined central location can stock spare parts that are adequate

for hot gas path inspection. Many gas turbine plants stock capital spare parts on-site, recognizing that

this parts availability minimizes the turn-around time required for major overhauls.

The planned maintenance program anticipates the needs of the equipment and is tailored to meet the re-

quirements of the system for utilization, reliability, and cost.

Types Of Inspections

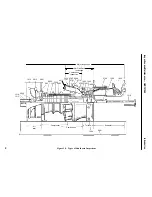

The types of inspections covered in this publication may be broadly classified in terms of unit “running”

and unit “shutdown” inspections. The running inspection is performed during start-up and while the unit

is operating. This inspection indicates the general condition of the gas turbine unit and its associated

equipment. The shutdown inspection is performed while the unit is at a standstill. The shutdown inspec-

tions include “Combustion,” “Hot Gas Path,” and “Major” inspections. These latter inspections require

disassembly of the turbine in varying degrees. See Figure 1-5.

Turbine starting reliability can be aided by conducting a “standby” inspection while the unit is shut

down. Routine servicing of the battery system, changing of filters, checking oil and water levels, clean-

ing relays, checking device settings and calibrations, lubrication and other general preventative mainte-

nance can be performed in off-peak hours without interrupting the availability of the turbine. Certain

designated accessories in need of repair or replacement may be returned to the factory on either a repair

and return basis or an exchange basis.

GE Company Field Service Representatives are available to provide technical direction or consultation

for repair and replacement.

Periodic test runs are also an essential part of a good maintenance program. It is highly recommended

that the unit be operated at load for at least 1 hour bi-monthly, and data recorded. It is recommended that

gas turbines on extended shutdown (three weeks or more) should be operated on turning gear or ratchet

for one hour each day to prevent the buildup of corrosive deposits in the turbine wheel dovetails or the

gas turbine should be operated at full speed, no load for one hour per week to dry the turbine out and

thereby prevent moisture condensation in the turbine dovetail crevices.

Special inspections such as borescope and eddy current probe, can be used to further plan periodic main-

tenance without interrupting availability. It is also recommended that visual inspections be performed

whenever there is personnel at the unit.

Summary of Contents for MS6001B

Page 2: ...Gas Turbine Inspection and Maintenance GEK 107048 I 2 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 4: ...Inspection and Maintenance Note THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 13: ...INSERT TAB INTRODUCTION ...

Page 14: ......

Page 25: ...INSERT TAB STANDARD PRACTICES ...

Page 26: ......

Page 87: ...INSERT TAB AUXILIARY CONTROLS SYSTEMS MAINTENANCE ...

Page 88: ......

Page 133: ...INSERT TAB SCHEDULED TURBINE MAINTENACE ...

Page 134: ......

Page 157: ...INSERT TAB COMBUSTION INSPECTION ...

Page 158: ......

Page 239: ...INSERT TAB HOT GAS PATH INSPECTION ...

Page 240: ......

Page 313: ...INSERT TAB MAJOR INSPECTION ...

Page 314: ......

Page 316: ...Inspection and Maintenance GEK 107048 Major Inspection 2 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 363: ...INSERT TAB MAINTENANCE FORMS ...

Page 364: ......