Inspection and Maintenance — GEK 107048

Major Inspection — Disassembly Procedures

MI-D-10

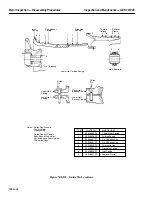

Figure MI-D.2. Guide Pin Locations.

Guide

Pin

Guide

Pin

Upper Half

Bearing Cap

Lower Half

Bearing Cap

Upper Half

Casing

Lower Half

Casing

No. 1 Bearing

Lower Half Turbine Casing

No. 2 Bearing

5

5

9

9

Inlet

Casing

Exhaust

Frame

Turbine

Casing

6

3

Discharge

Casing

7

1

1

Compressor

Casing

8

8

4

4

Notes: Guide Pins Found In

Tool Kit, Major

Disassembly

Guide Pins Are Used In

Body Round Stud Holes

Of Casings and Dowel Holes

Of Bearing Caps.

ITEM

GUIDE PIN

WHERE USED

1

248A4880 P4

Compressor Casing

3

295A9609 P2

Turbine Casing

4

295A9601 P1

No. 1 Bearing Cap

5

295A9601 P2

No. 2 Bearing Cap

6

295A9609 P3

Turbine Casing

7

295A9609 P1

Discharge Casing

8

295A9600 P1

Inlet Casing

9

295A9601 P3

Exhaust Frame

Summary of Contents for MS6001B

Page 2: ...Gas Turbine Inspection and Maintenance GEK 107048 I 2 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 4: ...Inspection and Maintenance Note THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 13: ...INSERT TAB INTRODUCTION ...

Page 14: ......

Page 25: ...INSERT TAB STANDARD PRACTICES ...

Page 26: ......

Page 87: ...INSERT TAB AUXILIARY CONTROLS SYSTEMS MAINTENANCE ...

Page 88: ......

Page 133: ...INSERT TAB SCHEDULED TURBINE MAINTENACE ...

Page 134: ......

Page 157: ...INSERT TAB COMBUSTION INSPECTION ...

Page 158: ......

Page 239: ...INSERT TAB HOT GAS PATH INSPECTION ...

Page 240: ......

Page 313: ...INSERT TAB MAJOR INSPECTION ...

Page 314: ......

Page 316: ...Inspection and Maintenance GEK 107048 Major Inspection 2 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 363: ...INSERT TAB MAINTENANCE FORMS ...

Page 364: ......