Major Inspection — Disassembly Procedures

Inspection and Maintenance — GEK 107048

MI-D-5

Operation 5 — How to Remove Inlet Duct Elbow

Note:

Due to variations in design of inlet duct work, refer to the Duct Ar-

rangement, Inlet drawing (MLA041) in the Parts Lists and Drawings,

Volume Service Manual for bolting details.

1. Support the elbow to prevent damage to the expansion joint when the elbow is released from the

adjacent duct work.

2. Unbolt the duct work from the elbow and the transition piece.

CAUTION

The inlet duct elbow weighs approximately 7100 pounds

and should be rigged accordingly when lifting.

3. Lift the elbow straight up out of the lagging and set on blocking which supports the throat and aft

gussets. Do not use the expansion joint for support.

4. Unbolt the transition piece from the inlet plenum.

CAUTION

The inlet transition piece weighs approximately 3400

pounds and should be rigged accordingly when lifting.

5. Lift the transition piece from the inlet plenum and set on blocking. Cover the top opening.

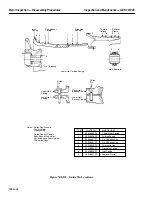

Operation 6 — How to Remove the Upper Half of the Inlet Plenum

1. Remove the inlet extension wings on the left and right sides of the plenum.

Note:

The inlet plenum extension wings weigh approximately 1600 pounds

and should be rigged accordingly for lifting.

2. Remove and/or disconnect any conduit runs, wiring, CO

2

piping or any other items attached to

the upper half of the forward and aft inlet plenum walls.

3. Unbolt the vertical and horizontal joints on the forward and aft walls.

4. Rig to lift the plenum using two lengths of timber spacing wedged forward to aft on the outer extre-

mities to keep the plenum from disforming when being lifted.

Note:

The upper half inlet plenum weighs approximately 1200 pounds and

should be rigged accordingly for lifting.

5. Check to ensure the upper half plenum is mechanically free.

6. Lift the upper half plenum off and set on suitable blocking.

Summary of Contents for MS6001B

Page 2: ...Gas Turbine Inspection and Maintenance GEK 107048 I 2 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 4: ...Inspection and Maintenance Note THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 13: ...INSERT TAB INTRODUCTION ...

Page 14: ......

Page 25: ...INSERT TAB STANDARD PRACTICES ...

Page 26: ......

Page 87: ...INSERT TAB AUXILIARY CONTROLS SYSTEMS MAINTENANCE ...

Page 88: ......

Page 133: ...INSERT TAB SCHEDULED TURBINE MAINTENACE ...

Page 134: ......

Page 157: ...INSERT TAB COMBUSTION INSPECTION ...

Page 158: ......

Page 239: ...INSERT TAB HOT GAS PATH INSPECTION ...

Page 240: ......

Page 313: ...INSERT TAB MAJOR INSPECTION ...

Page 314: ......

Page 316: ...Inspection and Maintenance GEK 107048 Major Inspection 2 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 363: ...INSERT TAB MAINTENANCE FORMS ...

Page 364: ......