Major Inspection — Disassembly Procedures

Inspection and Maintenance — GEK 107048

MI-D-3

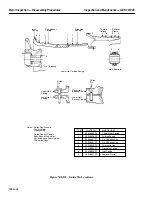

d. The indicator must be placed in such manner to permit face readings to be taken without being

affected by end float (thrust) of the accessory gear shaft when turning the shaft.

e. Rotate the accessory gear coupling with the alignment fixture and dial indicator attached until

indicator is aligned on the top vertical face mark. Set dial indicator to read zero “0.”

f. Rotate the accessory gear coupling (and alignment fixture) through one full revolution (360

°

)

take readings at each face mark (90

°

). Record the dial indicator readings.

Note:

All readings must repeat three consecutive times to be considered accu-

rate.

The indicators should return to “0” (corrected reading of zero for the

face and rim indicators) when returning to the top end of the vertical

mark. If they do not, check tightness of set-up and repeat readings. Re-

fer to the Basic Alignment Instructions (Field) in the Reference Draw-

ings section of this Service Manual.

g. Place dial indicator to read from the fixture to the rim of the turbine coupling flange.

h. Take rim readings in the same manner, except that no correction is necessary for axial move-

ment of the shaft. Record all readings on Inspection Form PGS/GT-FF-6115.

Operation 2 — Perform Combustion Inspection Disassembly Operations No. 1 Through No. 15

CAUTION

Before proceeding with a combustion inspection ensure

that the gas turbine electrical power is tagged-out; CO

2

system is deactivated, liquid fuel system is purged, deacti-

vated and/or the gas supply is blanked off. See Standard

Practices section, in this Service Manual.

Note:

Refer to the Combustion Inspection section of this Service Manual for

the following disassembly operations.

1. Prepare turbine compartment roof for removal.

2. Remove turbine compartment roof and side panels.

3. Remove cooling water lines from flame detectors.

4. Remove the flame detectors.

5. Remove primary gas fuel lines (if applicable).

Note:

In addition to the gas fuel lines to the fuel nozzles, unbolt and remove

the upper half gas manifold pipe also.

6. Remove transfer fuel gas lines.

Summary of Contents for MS6001B

Page 2: ...Gas Turbine Inspection and Maintenance GEK 107048 I 2 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 4: ...Inspection and Maintenance Note THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 13: ...INSERT TAB INTRODUCTION ...

Page 14: ......

Page 25: ...INSERT TAB STANDARD PRACTICES ...

Page 26: ......

Page 87: ...INSERT TAB AUXILIARY CONTROLS SYSTEMS MAINTENANCE ...

Page 88: ......

Page 133: ...INSERT TAB SCHEDULED TURBINE MAINTENACE ...

Page 134: ......

Page 157: ...INSERT TAB COMBUSTION INSPECTION ...

Page 158: ......

Page 239: ...INSERT TAB HOT GAS PATH INSPECTION ...

Page 240: ......

Page 313: ...INSERT TAB MAJOR INSPECTION ...

Page 314: ......

Page 316: ...Inspection and Maintenance GEK 107048 Major Inspection 2 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 363: ...INSERT TAB MAINTENANCE FORMS ...

Page 364: ......