Major Inspection — Reassembly Procedures

Inspection and Maintenance — GEK 107048

MI-R-1

1

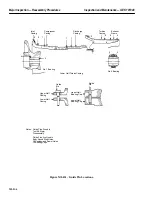

Figure MI-R.3. Exhaust Plenum Seal Segments, Forward and AFT Sides Assembly.

Two (2) Layers

Staggered 7 Seg.

Per Layer (14 Total)

(See Note)

0.125 (Min)

Exh. Plenum

Two (2) Layers

Staggered 7 Seg.

Per Layer (14 Total)

(See Note)

Inner Barrel

Seven (7) Layers

Of Bir-Felt

Folded As Shown

Eight (8) Clips Eq. Sp.

Do Not Pinch Ring

Maintain 0.000 to

0.010 Loose Weld

to Exh. Plenum

Exh. Hood

Frame

See

Enlarged View

(Forward)

See

Enlarged View

(Forward)

NOTE

Assemble Gasket Between Two Layers

Of Seals With Joints On the Horizontal

C Maximum Gap At Joints – 0.125 Inch

L

Summary of Contents for MS6001B

Page 2: ...Gas Turbine Inspection and Maintenance GEK 107048 I 2 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 4: ...Inspection and Maintenance Note THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 13: ...INSERT TAB INTRODUCTION ...

Page 14: ......

Page 25: ...INSERT TAB STANDARD PRACTICES ...

Page 26: ......

Page 87: ...INSERT TAB AUXILIARY CONTROLS SYSTEMS MAINTENANCE ...

Page 88: ......

Page 133: ...INSERT TAB SCHEDULED TURBINE MAINTENACE ...

Page 134: ......

Page 157: ...INSERT TAB COMBUSTION INSPECTION ...

Page 158: ......

Page 239: ...INSERT TAB HOT GAS PATH INSPECTION ...

Page 240: ......

Page 313: ...INSERT TAB MAJOR INSPECTION ...

Page 314: ......

Page 316: ...Inspection and Maintenance GEK 107048 Major Inspection 2 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 363: ...INSERT TAB MAINTENANCE FORMS ...

Page 364: ......