Inspection and Maintenance — GEK 107048

Hot Gas Path Inspection — Inspection Procedures

HGP-I-16

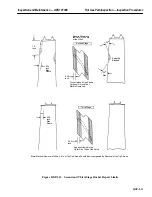

Shroud Tip Rework

Rework and metal removal is allowed in the cross-hatched areas. No rework is permitted which pene-

trates below the center section. See Figure HGP-I.15.

CAUTION

Equal amounts of material should be removed from the

leading and trailing edges.

Operation 4 — How to Inspect Shroud Blocks

1. Visually check the shrouds segments and hook fits for deposits, corrosion, erosion (pitting), cracks

and nicks or dents. Record findings on Inspection Form PGS/GT-FF-6098, PGS/GT-FF-6101 and

PGS/GT-FF-6104.

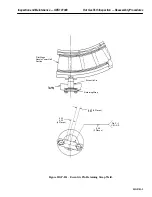

2. Visually inspect the shroud seals for distortion, rubs, wear, and missing pieces. See Figure

HGP-I.16.

Note:

The shrouds do not have to be disassembled from the turbine casing for

this inspection.

First Stage Shrouds

Turbine shroud block cracks are a result of low cycle thermal fatigue or thermal compressive over-

load. The cracks will propagate into the metal until the operating stress levels at the crack front are

sufficiently reduced. The cracks are generated normal to the gas path surface and are not smooth in

nature. Experience indicates that pieces of the shroud do not come out, and foreign object damage

is not anticipated.

If two or more cracks are diverging and it appears that a piece may come out, then the block should

be replaced. Also, if a crack goes greater than 80% through the metal thickness at any borescope hole,

the block should be replaced.

Corrosion of the first-stage shrouds is generally the result of contaminants in the air or fuel. Excessive

corrosion should be investigated; it may lead to loss of turbine stage performance.

Metal removal that leaves a smooth undulating surface or scalloped gas path surface is usually due

to abrasive materials in the cycle air or the fuel. Excessive erosion should be investigated.

Severe oxidation or ablation of the gas path surface may be caused by operation outside of specifica-

tion, including improper control system calibration and liquid carry-over in gas fuels. Severe oxida-

tion or ablation may be an indication of serious problems that could lead to turbine damage and should

be investigated. Metal loss of 1/8 inch or more in any case should be investigated.

Note:

Contact GE Representative for disposition if blocks are out of limits.

Summary of Contents for MS6001B

Page 2: ...Gas Turbine Inspection and Maintenance GEK 107048 I 2 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 4: ...Inspection and Maintenance Note THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 13: ...INSERT TAB INTRODUCTION ...

Page 14: ......

Page 25: ...INSERT TAB STANDARD PRACTICES ...

Page 26: ......

Page 87: ...INSERT TAB AUXILIARY CONTROLS SYSTEMS MAINTENANCE ...

Page 88: ......

Page 133: ...INSERT TAB SCHEDULED TURBINE MAINTENACE ...

Page 134: ......

Page 157: ...INSERT TAB COMBUSTION INSPECTION ...

Page 158: ......

Page 239: ...INSERT TAB HOT GAS PATH INSPECTION ...

Page 240: ......

Page 313: ...INSERT TAB MAJOR INSPECTION ...

Page 314: ......

Page 316: ...Inspection and Maintenance GEK 107048 Major Inspection 2 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 363: ...INSERT TAB MAINTENANCE FORMS ...

Page 364: ......