Introduction

Inspection and Maintenance

I–2

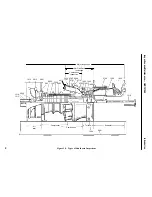

The factors having the greatest influence on the life of parts for any given machine are shown in Fig-

ure 1-1.

Fuel

The effect of the type of fuel on parts life is associated with the radiant energy in the combustion

process and the ability to atomize the various liquid fuels. Therefore, natural gas, which does not

require atomization, has the lowest level of radiant energy and will produce the longest life of parts.

Natural gas has been the traditional fuel for use with gas turbines. Due to the need to back up an inter-

ruptible gas supply many gas turbines are dual fuel with a distillate fuel oil used as the alternate fuel.

Contaminants in the fuel also affect maintenance intervals. This is particularly true for liquid fuels

in which dirt results in accelerated replacement of pumps, metering elements, and fuel nozzles. Con-

taminants in fuel gas can erode or corrode control valves and fuel nozzles.

Starting Frequency

Each stop and start of a gas turbine subjects the hot gas path to significant thermal cycles. Control

systems are designed and adjusted to minimize this effect. However, a gas turbine with frequent

starting and stopping requirements will demonstrate parts lives that are shorter than those for a simi-

lar unit in continuous-duty service. See Figure 1-3.

Load Cycle

The load cycle of the gas turbine, up to its continuous rating, will have little effect on parts lives,

provided it does not require frequent and rapid load changes.

Environment

The condition of the inlet air to the gas turbine can have a significant effect on maintenance costs

and intervals if it is either abrasive or corrosive. If abrasives are in the inlet air (e.g., as from sand

storms), careful attention should be paid to inlet filtering in order to minimize this effect.

If the gas turbine is to be operated in a corrosive atmosphere (for example, one with salts), careful

attention should be paid to the location of the inlet air arrangement and the application of correct

materials and protective coatings. It is essential during the planning stages of an application to rec-

ognize any abrasive or corrosive contaminants and to take the necessary steps to minimize them.

Contaminants in the fuel and air are additive.

Maintenance Practices

Parts condition information is based on estimates only, and will vary with machines and specific operat-

ing conditions. However, estimates are based on previous experience and can be very useful in planning

a maintenance program. As actual operating data is accumulated on a specific application, adjustments

of inspection cycles should be the next step in a well-planned program.

Initial inspection planning can be based on the combustion inspection schedule, hot gas path inspection

schedule, and major inspection schedule tailored to your unit and estimated outage requirements listed

in Figure 1-4.

Summary of Contents for MS6001B

Page 2: ...Gas Turbine Inspection and Maintenance GEK 107048 I 2 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 4: ...Inspection and Maintenance Note THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 13: ...INSERT TAB INTRODUCTION ...

Page 14: ......

Page 25: ...INSERT TAB STANDARD PRACTICES ...

Page 26: ......

Page 87: ...INSERT TAB AUXILIARY CONTROLS SYSTEMS MAINTENANCE ...

Page 88: ......

Page 133: ...INSERT TAB SCHEDULED TURBINE MAINTENACE ...

Page 134: ......

Page 157: ...INSERT TAB COMBUSTION INSPECTION ...

Page 158: ......

Page 239: ...INSERT TAB HOT GAS PATH INSPECTION ...

Page 240: ......

Page 313: ...INSERT TAB MAJOR INSPECTION ...

Page 314: ......

Page 316: ...Inspection and Maintenance GEK 107048 Major Inspection 2 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 363: ...INSERT TAB MAINTENANCE FORMS ...

Page 364: ......