Introduction

Inspection and Maintenance

I–4

Combustion Inspection

A brief shutdown inspection is required to change out fuel nozzles and to check the combustion lin-

ers transition pieces and crossfire tubes. These parts require the most frequent attention, as contin-

ued operation with a deteriorated combustion system can result in much shortened life of the down-

stream parts, such as turbine nozzles and buckets. It is also inherent in the gas turbine design that

these parts are the first to require repair or replacement. Therefore, the importance of this inspection

in the maintenance program must be emphasized.

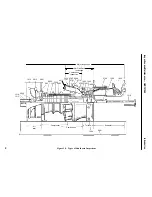

Figure 1-5 shows these components in relationship to one another.

A visual inspection of the leading edge of the first-stage turbine nozzle partitions and buckets should

be made during the combustion inspection to note any wear or deterioration of these parts. This in-

spection will help to establish the schedule for the Hot Gas Path inspection.

The combustion liners, transition pieces, crossfire tubes, and fuel nozzles should be removed and

replaced with new or repaired liners, transition pieces, crossfire tubes and new or cleaned fuel

nozzles. This procedure reduces downtime to a minimum and the removed liners, transition pieces,

crossfire tubes, and fuel nozzles can be cleaned, inspected and repaired later when it is more conve-

nient.

After the combustion inspection is completed and the turbine has been returned to service, the re-

moved liners, and transition pieces can be bench inspected and repaired if necessary, by competent

service personnel, or off-site at a qualified service facility. Off-site cleaning inspection, and repair

of the liners and transition pieces is recommended, since this activity can best be performed where

specialized equipment and fixtures are available.

The removed fuel nozzles can be cleaned and calibrated on site. Fuel nozzles should be stored in

sets for use at the next inspection.

Hot Gas Path Inspection

The Hot Gas Path inspection includes the Combustion Inspection just described and, in addition,

a detailed inspection of the turbine nozzles and turbine buckets. To perform this inspection, the top

half of the turbine case (shell), and the first-stage nozzle must be removed. The second-stage nozzle,

the third-stage nozzle, and the turbine buckets will be inspected visually while still in place in the

unit. A complete set of turbine clearances should also be taken during any inspection of the hot gas

path. Figure 1-5 shows the components involved in the hot gas path inspection.

As with the combustion inspection, it is recommended that replacement combustion liners, fuel

nozzles and transition pieces be available for installation at the conclusion of the visual inspection.

The removed parts can then be inspected at a qualified service facility and returned to stock for use

during the next inspection. It is also recommended that the Hot Gas Path inspection be conducted

under the technical direction of the GE Company Field Service Representative for accurate analysis

of inspection data and most effective use of outage time.

Summary of Contents for MS6001B

Page 2: ...Gas Turbine Inspection and Maintenance GEK 107048 I 2 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 4: ...Inspection and Maintenance Note THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 13: ...INSERT TAB INTRODUCTION ...

Page 14: ......

Page 25: ...INSERT TAB STANDARD PRACTICES ...

Page 26: ......

Page 87: ...INSERT TAB AUXILIARY CONTROLS SYSTEMS MAINTENANCE ...

Page 88: ......

Page 133: ...INSERT TAB SCHEDULED TURBINE MAINTENACE ...

Page 134: ......

Page 157: ...INSERT TAB COMBUSTION INSPECTION ...

Page 158: ......

Page 239: ...INSERT TAB HOT GAS PATH INSPECTION ...

Page 240: ......

Page 313: ...INSERT TAB MAJOR INSPECTION ...

Page 314: ......

Page 316: ...Inspection and Maintenance GEK 107048 Major Inspection 2 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 363: ...INSERT TAB MAINTENANCE FORMS ...

Page 364: ......