Inspection and Maintenance — GEK 107048

Combustion Inspection — Inspection Procedures

CI-I-18

Table CI-3

Inspection Limits, Crossfire Tubes and Retainers

CAUTION

The inspection criteria in this Table CI-3 applies to

General Electric Company supplied crossfire tubes and

retainers only.

Inspect

Maximum Acceptable

Limits

Disposition (For Parts

Beyond Max. Limits)

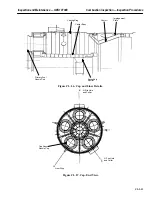

Inner Crossfire Tubes

1. Burn through; missing metal

None

Replace

2. Distortion

None

Replace

3. Cracks

None

Replace

4. Flange wear

0.14 inch minimum thickness

Replace

5. Tube wear

0.11 inch minimum thickness

Replace

Crossfire Tube Spring Retainers

1. Wear

20% of original material

Replace

2. Evidence of distortion

None

Replace

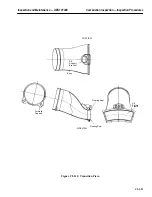

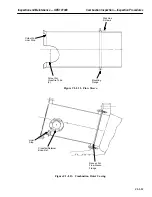

c. Aft frame internal corner cracks.

d. Aft frame external corner cracks.

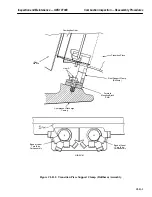

e. Forward brackets for weld cracks right and left sides.

f. Transition piece body for cracks.

2. Use the transition piece inspection criteria Table CI-4 to completely inspect the transition pieces

after fluorescent penetrant test.

3. Record findings on Inspection Form PGS/GT-FF-6407.

4. Repair welding procedures.

Summary of Contents for MS6001B

Page 2: ...Gas Turbine Inspection and Maintenance GEK 107048 I 2 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 4: ...Inspection and Maintenance Note THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 13: ...INSERT TAB INTRODUCTION ...

Page 14: ......

Page 25: ...INSERT TAB STANDARD PRACTICES ...

Page 26: ......

Page 87: ...INSERT TAB AUXILIARY CONTROLS SYSTEMS MAINTENANCE ...

Page 88: ......

Page 133: ...INSERT TAB SCHEDULED TURBINE MAINTENACE ...

Page 134: ......

Page 157: ...INSERT TAB COMBUSTION INSPECTION ...

Page 158: ......

Page 239: ...INSERT TAB HOT GAS PATH INSPECTION ...

Page 240: ......

Page 313: ...INSERT TAB MAJOR INSPECTION ...

Page 314: ......

Page 316: ...Inspection and Maintenance GEK 107048 Major Inspection 2 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 363: ...INSERT TAB MAINTENANCE FORMS ...

Page 364: ......