Inspection and Maintenance — GEK 107048

Combustion Inspection — Inspection Procedures

CI-I-20

Table CI-4

— Continued

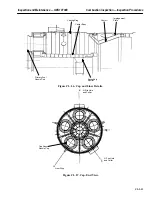

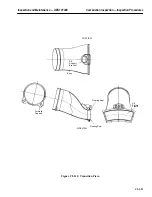

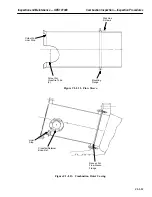

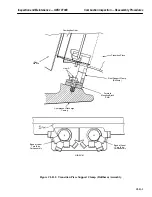

Inspection Limits, Transition Piece Assembly

See Figure CI-I.10 and CI-I.11

CAUTION

The inspection criteria in this Table CI-4 applies to

General Electric Company supplied transition pieces only.

Inspect

Maximum Acceptable

Limits

Disposition (For Parts

Beyond Max. Limits)

Floating Seal Retainers

1. Weld or retainer cracks

None

*Replace

2. Wear

50% of original material

*Replace

Floating Seals

1. Wear

50% of original material

thickness

*Replace

2. Cracks

None

*Replace

3. Radial movement

0.080 inch minimum from

nominal diameter

*Replace

Side Seals

1. Surface Wear

0.050 inch metal removal

Replace

2. Cracks

None

Replace

3. Distortion

0.020 inch out of flat

Replace

Forward Support (Bullhorn)

1. Cracks

None

*Replace

2. Slot wear

0.040/0.060 inch

from original dimension

*Replace

*“Replace” does not mean liner must be scrapped; part can be repaired by qualified General Electric

Company personnel.

Summary of Contents for MS6001B

Page 2: ...Gas Turbine Inspection and Maintenance GEK 107048 I 2 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 4: ...Inspection and Maintenance Note THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 13: ...INSERT TAB INTRODUCTION ...

Page 14: ......

Page 25: ...INSERT TAB STANDARD PRACTICES ...

Page 26: ......

Page 87: ...INSERT TAB AUXILIARY CONTROLS SYSTEMS MAINTENANCE ...

Page 88: ......

Page 133: ...INSERT TAB SCHEDULED TURBINE MAINTENACE ...

Page 134: ......

Page 157: ...INSERT TAB COMBUSTION INSPECTION ...

Page 158: ......

Page 239: ...INSERT TAB HOT GAS PATH INSPECTION ...

Page 240: ......

Page 313: ...INSERT TAB MAJOR INSPECTION ...

Page 314: ......

Page 316: ...Inspection and Maintenance GEK 107048 Major Inspection 2 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 363: ...INSERT TAB MAINTENANCE FORMS ...

Page 364: ......