Inspection and Maintenance — GEK 107048

Hot Gas Path Inspection — Reassembly Procedures

HGP-R-10

Operation 4 — How to Install Upper Half First Stage Nozzle (With Support Pad and Retainer)

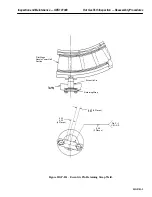

1. Check that the support pad groove in the first stage nozzle support ring is clean and free from burrs

on the tongue or in the groove. See Figure HGP-R.5.

Note:

The upper half first stage nozzle assembly weighs approximately 380

pounds.

2. Rig and lift the upper half first stage nozzle assembly (ends pointing down) and carefully lower

it onto the upper half support ring and lower half first stage nozzle.

3. Install and tighten the horizontal joint bolts.

Operation 4 — How to Install Upper Half First Stage Nozzle (With Tangential Support Pin)

1. Check to insure that the groove in the first-stage nozzle support ring is clean and that there are

no burrs on the tongue or in the groove prior to installing the upper half first-stage nozzle. See

Figure HGP-R.5.

2. Rig and lift the upper half first-stage nozzle assembly (ends pointing down) and lower it onto the

upper half support ring.

3. Apply a light coating of Fel Pro C-102 anti-seize compound to the tangential support pins and

install the pins into the support ring and first-stage nozzle support lugs.

4. Assemble the support pin retainer plate, coat the retainer plate bolt with anti-seize compound,

install and tighten the bolt. Bend the locking tabs on the retainer plate to keep the bolt from rotat-

ing. See Figure HGP-R.2.

5. Install and tighten the first-stage nozzle horizontal joint bolts.

Operation 5 — How to Install Upper Half Second and Third Stage Nozzle Segments and Radial

Retaining Pins

Note:

This operation assumes that the diaphragm and nozzle segments are

being installed as one assembly.

1. Thoroughly clean the hook fits. Buffing the nozzle hook fits may be helpful prior to applying

anti-seize compound. Apply a light coating of Fel Pro C-102 anti-seize compound to the hook

fits.

CAUTION

Use of anti-seize compound must be restricted to a thin

film such that the compound is not forced into the inner

gas path. Should this occur, it must be carefully removed.

2. Install the nozzle forward and aft seals to the nozzle segment in accordance with the Nozzle Ar-

rangement Drawings in the Parts Lists and Drawings Volume of the Service Manual.

Summary of Contents for MS6001B

Page 2: ...Gas Turbine Inspection and Maintenance GEK 107048 I 2 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 4: ...Inspection and Maintenance Note THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 13: ...INSERT TAB INTRODUCTION ...

Page 14: ......

Page 25: ...INSERT TAB STANDARD PRACTICES ...

Page 26: ......

Page 87: ...INSERT TAB AUXILIARY CONTROLS SYSTEMS MAINTENANCE ...

Page 88: ......

Page 133: ...INSERT TAB SCHEDULED TURBINE MAINTENACE ...

Page 134: ......

Page 157: ...INSERT TAB COMBUSTION INSPECTION ...

Page 158: ......

Page 239: ...INSERT TAB HOT GAS PATH INSPECTION ...

Page 240: ......

Page 313: ...INSERT TAB MAJOR INSPECTION ...

Page 314: ......

Page 316: ...Inspection and Maintenance GEK 107048 Major Inspection 2 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 363: ...INSERT TAB MAINTENANCE FORMS ...

Page 364: ......