Major Inspection — Reassembly Procedures

Inspection and Maintenance — GEK 107048

MI-R-3

5. Apply a thin film of anti-seize compound to the bolts, install bolting and torque the horizontal

joint.

6. Check the outside diameter of the upper and lower half casings at the horizontal joint to insure

that the mating joints do not have a step greater than 0.0015 in.

7. Using a piece of 0.0015 in. feeler check the aft end inner bore horizontal joint at the rabbet fit.

This joint fit should not exceed 0.0015 in.

Operation 4 — How to Install Compressor Discharge and Aft Compressor Casings

Note:

Later vintage units do not have an aft compressor casing, it has been

combined as a one piece casing with the forward compressor casing. If

the unit does have an aft compressor casing it can be installed along

with the compressor discharge casing as a single unit.

1. Clean and deburr all mating joints.

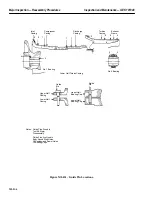

2. Rig to lift the compressor discharge and aft compressor casing. Install the guide pins. See Figure

MI-R.1.

3. Apply joint compound on the surface of the horizontal joints only, and only for a distance of one

inch on both sides of the four way joint. Do not apply joint compound to the vertical joint. Refer

to Section 2, Standard Practices, solvents, sealers and cleaners in this Service Manual.

4. Carefully lower the casing into position on the lower half casings using the guide pins installed.

5. Apply anti-seize compound to all bolting.

6. Remove guide pins and install bolting to the horizontal joints.

7. Tighten the horizontal joint bolts starting at the mid point of the horizontal joints. Torque the bolt-

ing working alternately left and right, forward and aft until all bolting on the horizontal joints are

tight. See Figure MI-R.2.

8. Install the vertical joint bolts between the inner compressor discharge case and the compressor

discharge case. Tighten and torque the bolts starting at the vertical centerline and alternately

working toward the horizontal joint.

Operation 5 — How to Install Upper Half First Stage Nozzle Support Ring

1. Clean and deburr the mating joints.

2. Apply a light coating of anti-seize compound to the horizontal joint dowels and the horizontal

and vertical joint bolts.

3. Rig and lift the first-stage nozzle support ring and and lower into position on the lower half.

4. Assemble the support ring locating shim.

5. Install all horizontal and vertical bolting. Tighten and torque bolting.

Summary of Contents for MS6001B

Page 2: ...Gas Turbine Inspection and Maintenance GEK 107048 I 2 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 4: ...Inspection and Maintenance Note THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 13: ...INSERT TAB INTRODUCTION ...

Page 14: ......

Page 25: ...INSERT TAB STANDARD PRACTICES ...

Page 26: ......

Page 87: ...INSERT TAB AUXILIARY CONTROLS SYSTEMS MAINTENANCE ...

Page 88: ......

Page 133: ...INSERT TAB SCHEDULED TURBINE MAINTENACE ...

Page 134: ......

Page 157: ...INSERT TAB COMBUSTION INSPECTION ...

Page 158: ......

Page 239: ...INSERT TAB HOT GAS PATH INSPECTION ...

Page 240: ......

Page 313: ...INSERT TAB MAJOR INSPECTION ...

Page 314: ......

Page 316: ...Inspection and Maintenance GEK 107048 Major Inspection 2 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 363: ...INSERT TAB MAINTENANCE FORMS ...

Page 364: ......