Inspection and Maintenance — GEK 107048

Hot Gas Path Inspection — Disassembly Procedures

HGP-D-6

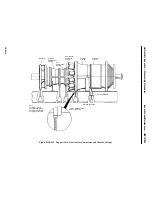

Figure HGP-D.2. Support Jack Locations for Compressor and Turbine Casings.

Inlet Bell

Forward

Compressor

Casing

Aft

Compressor

Casing

Compressor

Discharge

Casing

Turbine

Casing

Exhaust

Frame

Jacking Platform

Mechanical Jacks

NO. 3

NO. 4

NO. 5

NO. 1

Turbine – Flange To Flange

Weight = 91,650 lbs.

NOTE:

Position No. 5 is not

Required if Compressor

Casing is a Single Piece

Casing. (No Aft Casing)

Summary of Contents for MS6001B

Page 2: ...Gas Turbine Inspection and Maintenance GEK 107048 I 2 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 4: ...Inspection and Maintenance Note THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 13: ...INSERT TAB INTRODUCTION ...

Page 14: ......

Page 25: ...INSERT TAB STANDARD PRACTICES ...

Page 26: ......

Page 87: ...INSERT TAB AUXILIARY CONTROLS SYSTEMS MAINTENANCE ...

Page 88: ......

Page 133: ...INSERT TAB SCHEDULED TURBINE MAINTENACE ...

Page 134: ......

Page 157: ...INSERT TAB COMBUSTION INSPECTION ...

Page 158: ......

Page 239: ...INSERT TAB HOT GAS PATH INSPECTION ...

Page 240: ......

Page 313: ...INSERT TAB MAJOR INSPECTION ...

Page 314: ......

Page 316: ...Inspection and Maintenance GEK 107048 Major Inspection 2 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 363: ...INSERT TAB MAINTENANCE FORMS ...

Page 364: ......