Inspection and Maintenance — GEK 107048

Major Inspection — Reassembly Procedures

MI-R-2

12. Check the anti-rotation pin and install the upper half number two bearing liner.

13. Apply joint sealant to bearing strap and install bearing strap shims and bearing strap.

14. Lightly coat the dowel pins and bolts with anti-seize compound, install dowel pins, bolts and

torque alternately.

15. Apply joint sealant to number two bearing housing, install upper half bearing housing to the lower

bearing housing.

16. Lightly coat dowel pins and bolts with anti-seize compound, install dowel pins and bolts. Torque

bolts alternately from the center of each flange joint outward.

17. Reconnect any instrumentation and tubing which was removed.

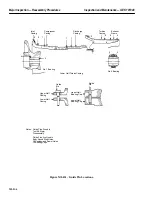

Operation 2 — Recheck Compressor Clearances and Thrust

CAUTION

The thrust bearings must be fully assembled when taking

thrust measurements. Any movement of the unit rotor

without fully assembled thrust bearings will cause the unit

journals to move axially in the bearing liners causing the

compressor blades to engage the stator blades. Such con-

tact can cause major blade damage.

1. Recheck all thrust and compressor clearances. Refer to disassembly operation 15, step 1 through

11 of this major inspection for procedure and clearances to be taken.

2. Record the thrust and clearance measurements on Inspection Forms PGS/GT-FF-6117, 6106 and

6108.

Operation 3 — How to Install Inner Compressor Discharge Casing

CAUTION

Inspect the inner case for cleanliness and foreign matter

prior to assembly of the top half casing.

1. Clean and deburr the horizontal flange on the lower half casing.

2. Assure the four dowel pins, two forward and two aft are assembled in the horizontal joint and the

tapped bolt holes are clean.

3. Rig to lift the top half inner compressor discharge casing. Lift the casing, clean and deburr the

horizontal joint flange.

4. Set the upper half inner compressor casing in place and assure that all dowels are in place.

Summary of Contents for MS6001B

Page 2: ...Gas Turbine Inspection and Maintenance GEK 107048 I 2 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 4: ...Inspection and Maintenance Note THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 13: ...INSERT TAB INTRODUCTION ...

Page 14: ......

Page 25: ...INSERT TAB STANDARD PRACTICES ...

Page 26: ......

Page 87: ...INSERT TAB AUXILIARY CONTROLS SYSTEMS MAINTENANCE ...

Page 88: ......

Page 133: ...INSERT TAB SCHEDULED TURBINE MAINTENACE ...

Page 134: ......

Page 157: ...INSERT TAB COMBUSTION INSPECTION ...

Page 158: ......

Page 239: ...INSERT TAB HOT GAS PATH INSPECTION ...

Page 240: ......

Page 313: ...INSERT TAB MAJOR INSPECTION ...

Page 314: ......

Page 316: ...Inspection and Maintenance GEK 107048 Major Inspection 2 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 363: ...INSERT TAB MAINTENANCE FORMS ...

Page 364: ......