Combustion Inspection — Inspection Procedures

Inspection and Maintenance — GEK 107048

CI-I-9

Inspect and Clean the Secondary Fuel Nozzles

1. Inspect parts for major carbon buildup and for plugged slots or orifices prior to cleaning. If oil or

water has leaked into any of the gas passages, the resulting deposits must be removed before reas-

sembly. Record observation on Inspection Form PGS/GT–FF–WS28.

2. The cleaning procedures for the secondary nozzle parts are the same as those described for the pri-

mary nozzles.

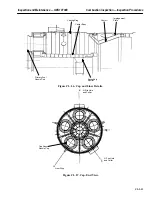

3. Inspect the outer diameter of the gas tip where it contacts the center body for wear. If metal loss

in this area is 0.015 inch or more, contact your General Electric Field Service Representative for

information concerning repair of this part.

Operation 4 — How to Reassemble the Secondary Fuel Nozzles

1. Since plastic coverings are often used to protect the surfaces of new or spare parts, be sure that

all plastic material is removed before reassembling the nozzle. Ensure that no plastic material re-

mains lodged on inside surfaces.

2. Do not use Teflon tape or liquid sealant anywhere in the fuel nozzle assembly.

3. Ensure that all gaskets are new. NEVER REUSE AN OLD GASKET.

4. Use Fel–Pro C–102 anti–seize compound on all threaded parts.

5. During reassembly of the fuel nozzle, use the torque values specified on the fuel nozzle assembly

drawing in the Parts Lists and Drawings Volume of the service manuals.

6. Use a torque wrench with a range from zero to approximately 20 percent above the maximum

torque required for assembly. The accuracy should be within

±

5 percent.

7. Using a suitable holding fixture, secure the fuel nozzle body with the fuel nozzle orifice pointing

up.

8. Wipe anti–seize compound lightly on the threads of the transition piece assembly and on the corre-

sponding threads in the fuel nozzle body.

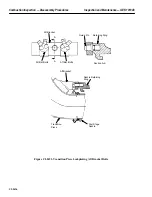

9. Carefully install a new metal O–ring into the groove in the transition piece making sure that they

are centered by the shoulder outside the gasket surfaces.

10. Install a new lock plate on the transition piece and screw the transition piece onto the body thread.

Using a socket wrench, torque the assembly to the value specified on the assembly drawing.

CAUTION

Torque the assembly only once. Under no circumstances

should the assembly be loosened and retorqued without

replacing the O–ring.

Summary of Contents for MS6001B

Page 2: ...Gas Turbine Inspection and Maintenance GEK 107048 I 2 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 4: ...Inspection and Maintenance Note THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 13: ...INSERT TAB INTRODUCTION ...

Page 14: ......

Page 25: ...INSERT TAB STANDARD PRACTICES ...

Page 26: ......

Page 87: ...INSERT TAB AUXILIARY CONTROLS SYSTEMS MAINTENANCE ...

Page 88: ......

Page 133: ...INSERT TAB SCHEDULED TURBINE MAINTENACE ...

Page 134: ......

Page 157: ...INSERT TAB COMBUSTION INSPECTION ...

Page 158: ......

Page 239: ...INSERT TAB HOT GAS PATH INSPECTION ...

Page 240: ......

Page 313: ...INSERT TAB MAJOR INSPECTION ...

Page 314: ......

Page 316: ...Inspection and Maintenance GEK 107048 Major Inspection 2 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 363: ...INSERT TAB MAINTENANCE FORMS ...

Page 364: ......