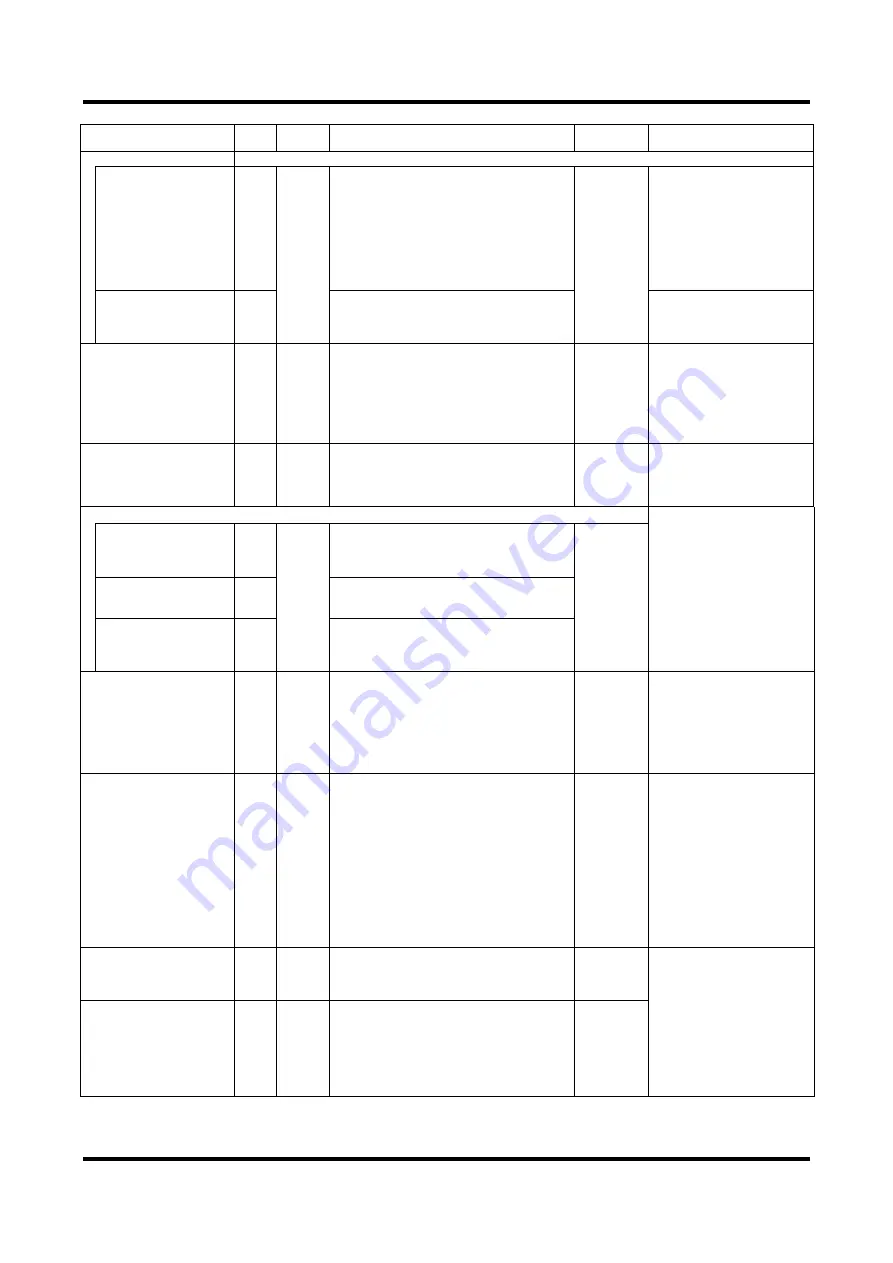

Appendix 3-4

TI71M01D06-01EN 3rd Edition: 2012.12.01

Name

Error

code

Recovery

Cause and condition detected

Action taken

at occurrence

Countermeasure

Overload

Motor coil line overload

22.1

Possible

The power-squared duty is calculated from the

current command value, but it exceeded the

designated value.

Perform current control without monitoring setting.

Limited current when the value became lower than

the cancellation current-squared duty value.

Error setup

register 1

dependent,

bits 27 to 24

Current

control was

executed

regardless of

its setting.

Review the operation cycle.

Set a longer

acceleration/deceleration

time.

Eliminate an external force

that is constantly being

applied.

The current-squared duty can be

checked by #386.

Heat

sink

over-heat

22.2

Detected a heat generation of 85

C or more inside

the drive.

Limited current while detecting, and cancelled it

when not detecting.

Check the ambient temperature

and installation environment of

the drive.

Excessive position deviation

23.0

Possible

The position deviation exceeded the user setup

value when position control was executed.

Acceleration/deceleration time is too short.

Servo tuning failure

Error setup

register 1

dependent,

bits 23 to 20

Set a longer

acceleration/deceleration

time.

Perform a servo tuning again,

and set an appropriate value.

Eliminate an external force

that interferes with the

motor's rotation.

Over-speed 24.0

Possible

The absolute value of the current velocity value

detected from SIG0 was more than the maximum

velocity of the motor.

The velocity exceeding the monitor #305 value

was detected.

Error setup

register 1

dependent,

bits 31 to 28

Set a longer

acceleration/deceleration

time.

Perform a servo tuning again,

and set an appropriate value.

Regeneration error

If a regenerative resistor is

not installed, install one.

If this error occurs when a

regenerative resistor is

already installed, review the

acceleration/deceleration

time and the operation

cycle.

The motor unit is rotated by

an external force.

Regenerative resistor

over-load

25.1

Not

possible

Excessive electric power was applied to a

regenerative resistor, and thus the allowable

electric power of the regenerative resistor was

exceeded.

Servo Off

Regeneration

error output

Regeneration FET

over-load

25.2

Excessive electric power was applied to a

regeneration FET, and thus the allowable electric

power of the regeneration FET was exceeded.

Regeneration

circuit

error

25.3

The RGN_FET status and RGN_ANS status

sampled at every msec were verified at every

32msec. This error occurred when a difference

exceeding 2 digits was detected in each on-duty.

Servo not ready

30.0

Possible

The Servo OFF state occurred during an axis

operation by internal control, or during an axis

operation by an external position command.

Servo OFF

Check the wiring, power

supply and PLC software so

that the IN_SERVO signal

does not change during an

operation.

Execute an axis operation

command after turning the

servo on.

Excessive position command

differential value

31.0

Possible

Attempted to execute an axis operation at a

velocity exceeding the maximum motor velocity set

by the user during an axis operation by internal

control, or during an axis operation by an external

position command.

If the number of commanded pulses per 1msec

exceeds the rate of maximum command

frequency, the excessive position command

differential value error (31.0 for error code)

appears.

Error setup

register 1

dependent,

bits 18 to 16

Set maximum rate of pulse input

so that it is less than the speed

monitored by #305 (Maximum

speed).

Set the commanded speed from

controller lower so that the pulse

input rate does not reach the

maximum

command frequency.

(If the pulse output frequency of

controller is unstable, it is

impossible to command pulses at

the maximum

command frequency.)

+ direction hardware EOT

42.0

Possible

A + direction EOT signal was detected during an

axis operation by internal control, during an axis

operation by an external position command, or

while moving in the + direction.

Error setup

register 2

dependent,

bits 31 to 28

Reduce the amount of

movement so that it does not

exceed the hardware EOT

sensor.

Change the conversion of

pulse units.

Is the sensor operating

normally? Is any noise

generated on the sensor

power supply?

Check the wiring connection

of the sensor.

- direction hardware EOT

43.0

Possible

A - direction EOT signal was detected during an

axis operation by internal control, during an axis

operation by an external position command, or

while moving in the - direction.

Error setup

register 2

dependent,

bits 27 to 24